Mining Contract: Wireless Mesh Mine Communication System

| Contract # | 200-2007-20388 |

|---|---|

| Start Date | 5/25/2007 |

| End Date | 2/27/2009 |

| Research Concept | This contract will design, adapt, construct, install, and evaluate a wireless mesh communication network in an underground coal mine. Past mining accidents have demonstrated that current communication systems are insufficient to support evacuation and rescue operations. A wireless mesh architecture allows radio communications between nodes without cabling. When a node receives a signal, it boosts the signal and routes it to other nodes that are further away. This process is repeated until the destination node is reached. Each node is capable of finding neighbor nodes, setting up connections, and determining optimal travel paths. As a result, mesh networks are self-healing: the network can still operate even when a node breaks down or a connection goes bad because signals are rerouted through other nodes. A mesh network can support communications between members of a group within the network without the support of external networks. This characteristic would be very valuable in an active mining section if the communications link between the section and the surface operations center were lost. |

| Topic Area |

Contract Status & Impact

This contract is complete. To receive a copy of the final report, send a request to mining@cdc.gov.

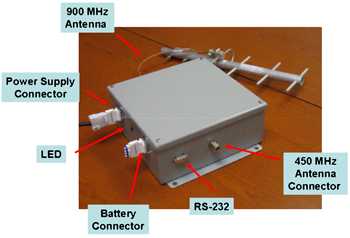

In October 2008, a pilot system was installed in International Coal Group, Wolf Run Mining Company's Sentinel mine near Philippi, WV. The system consists of a network of mesh nodes extending from the surface operations center to one of the mine's working sections. The network provides untethered voice and text communications and miner location tracking through handsets issued to each miner.

The network provides redundant communication links to the surface through an elevator shaft and a slope portal. Redundancy is extended to the working section by placing additional nodes so failure of any one node will not disrupt communications with the surface. Surviving nodes automatically reconfigure to reform a network. Special nodes were developed to interface with the mine's existing leaky feeder system to provide another option for redundant communication links to the surface. Battery backups provide power to the nodes should an emergency require the mine's electrical power to be shut off.

A handset within network coverage can itself act as a node to allow orphaned handsets out of network coverage to maintain communications. Handsets can also communicate with other handsets independent of the network. Tracking is accomplished when handsets are within range of one or more nodes. A situational awareness display in the surface operations center provides a mine map showing the miners' locations.

The L-3 ACCOLADE Wireless Mesh Communications System is MSHA- and West Virginia-approved. An industry demonstration was held at the Sentinel mine on November 13, 2008.

See Also

- Design and Demonstration of a Location Tracking System for Underground Coal Mines (Award 1)

- Development of a Wireless Test and Measurement Tool for Use in Mines

- Emergency Communications and Tracking

- Mine Communications Engineering and Compatibility Guidelines

- Passive Fiber Optic System for Locating, Tracking, and Communicating with Personnel in Coal Mines

- Refuge Alternatives in Underground Coal Mines

- Safe and Economical Inerting of Sealed Mine Areas

- Technology News 544 - New Measurement Tool to Validate Wireless Communications and Tracking Radio Signal Coverage in Mines

- Through-The-Earth Wireless Real-Time Two-Way Voice Communications

- Ultra-Low Frequency Through-the-Earth Communication Technology

- Page last reviewed: 7/18/2016

- Page last updated: 9/17/2012

- Content source: National Institute for Occupational Safety and Health, Mining Program

ShareCompartir

ShareCompartir