NOISE AND HEARING LOSS PREVENTION

Noise Controls

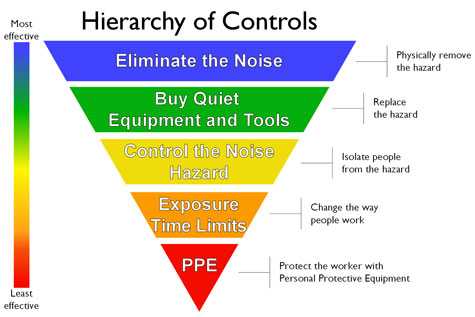

Occupational safety and health professionals use the Hierarchy of Control to determine how to implement feasible and effective controls. This approach groups actions by their likely effectiveness in reducing or removing the noise hazard.

Elimination Or Substitution: In most cases, the preferred approach is to eliminate the source of hazardous noise. When elimination is not possible, substitution of the loud equipment for quieter equipment may be the next best alternative to protect workers from hazardous noise.

Engineering and Administrative Controls: To the extent feasible, engineering controls, administrative controls, and work practices shall be used to ensure that workers are not exposed to noise at or above 85 dBA as an 8-hour TWA. Engineering controls require physical changes to the workplace such as redesigning equipment to eliminate noise sources and constructing barriers that prevent noise from reaching a worker. If engineering controls are not feasible, employers an explore potential administrative controls, such as scheduling that will minimize exposure, providing quiet and convenient lunch and break areas.

Personal Protective Equipment (PPE): When all options for eliminating or reducing the noise at the source are exhausted, hearing protection devices such as earplugs or earmuffs should be made available to workers, at no cost, to sufficiently attenuate noise so that their “real-world” exposure is below 85 dBA as an 8-hour TWA.

NIOSH – Controls for Noise Exposure

This resource provides information about solutions for reducing occupational noise exposures based on the Hierarchy of Control approach.

NIOSH Directory of Engineering Controls

This directory page links to NIOSH engineering control related webpages, projects, programs, tools and resources created to improve workplace health and safety.

NIOSH Buy Quiet Program

The NIOSH Buy Quiet initiative encourages companies and employers to select, purchase or rent, the lowest noise emitting power tools and machinery in order to reduce occupational noise exposure. This initiative provides information on equipment noise levels and encourages manufacturers to design quieter equipment.

NIOSH Power Tools Database

The database contains sound power levels, sound pressure levels, and vibrations data for a variety of common power tools that have been tested by researchers. This database also contains downloadable exposure and wave files.

NIOSH – Industrial Noise Control Manual

This historic document, originally published in 1975, contains essential information about noise control technology and a collection of 61 case histories of successful noise control projects.

OSHA Technical Manual – Noise, Hazard Abatement and Control

This OSHA technical manual provides technical information and guidance that OSHA Compliance Safety and Health Officers use to evaluate noise hazards in the workplace. The content is based on currently available research publications from NIOSH, OSHA, and other consensus standards.

NIOSH – Preventing Occupational Hearing Loss – A Practical Guide

This guide is intended to assist employers to develop and maintain hearing loss prevention programs; it provides practical information and guidelines on the eight major components of a hearing loss prevention program: (1) noise exposure monitoring, (2) engineering and administrative controls, (3) audiometric evaluation, (4) use of hearing protection devices, (5) education and motivation, (6) record keeping, (7) program evaluation, and (8) hearing loss prevention program audit.

- Page last reviewed: November 10, 2016

- Page last updated: November 10, 2016

- Content source:

- National Institute for Occupational Safety and Health Division of Applied Research and Technology

ShareCompartir

ShareCompartir