Mining Contract: Technology Upgrade of the Sarcos Snake Robot

| Contract # | 200-2015-M-62411 |

|---|---|

| Start Date | 5/1/2015 |

| End Date | 6/30/2016 |

| Research Concept | In a previous contract, NIOSH Mining worked with Sarcos, LLC, to adapt an existing robotic technology for mine rescue that Sarcos had originally developed for use by the Department of Defense. Sarcos completed that project in 2012 and delivered the finished product to NIOSH Mining’s Bruceton campus in Pittsburgh. After a period of testing the snake robot in various conditions and with multiple operators, NIOSH and MSHA (Mine Safety and Health Administration) staff identified a number of shortcomings of the robot that would keep it from achieving MSHA acceptance for use during mine rescue. This most recent contract was awarded in order for Sarcos to address those shortcomings and provide further hands-on training for NIOSH and MSHA personnel. |

| Topic Area |

Contract Status & Impact

This contract is complete. To receive a copy of the final report, send a request to mining@cdc.gov.

As a follow-up to a previous contract awarded to Sarcos, LLC., the company addressed several issues identified by NIOSH and MSHA personnel during preliminary testing of the snake robot at NIOSH’s Bruceton testing facility.

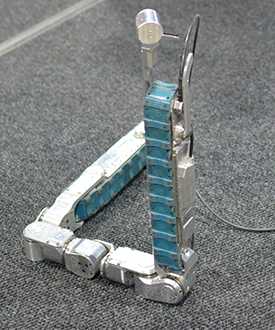

In the first contract, the snake robot technology was adapted to produce a version suitable for operations in underground mines, particularly in the case of a mining disaster. The mine-capable, tandem-track snake robot was crafted to:

- move at a rate of 1 to 2 miles per hour;

- maintain mobility through a debris field, including mud and standing water;

- operate tethered to cabling of sufficient strength to be lowered vertically 2,000 feet through a 4-inch diameter borehole;

- detect oxygen, methane, carbon monoxide, and temperature;

- enable two-way voice communication;

- provide a minimum of 200 feet of lateral illumination with color and infrared video; and

- receive power through both onboard batteries and the tether cable.

This second, 10-month contract tasked Sarcos with conducting a review of the onboard technologies and instruments and determining if any or all of the MSHA-approved instruments or technologies were still certified for use in a gassy underground coal mine. Additionally, Sarcos checked all batteries and ancillary components for any needed replacement or upgrade. Sarcos also fixed a more substantial issue found during testing.

During a water sump drive-through evaluation at the NIOSH test mine, the test team observed that the snake robot was not behaving as designed. The team speculated that perhaps one of the robot's seals had failed and allowed moisture or mud to enter the robot's housing. At the conclusion of testing, the snake robot was packaged and shipped back to Sarcos’ Salt Lake City headquarters. Upon further examination, Sarcos determined that the robot's errant operation was caused by the failure of a commercial off-the-shelf (COTS) circuitry. The contractor then replaced the circuitry.

After performing the repairs and updating the robot's user manual, Sarcos shipped the robot back to NIOSH Mining's Bruceton campus and provided user training for NIOSH and MSHA personnel.

With the changes and fixes addressed and training accomplished, the snake robot is anticipated to be ready for deployment by MSHA to any mining disaster or similar catastrophic disasters.

See Also

- Adaptive-Noise-Cancellation Techniques for Through-the-Earth Electromagnetics: Volume III

- Analytical Investigations of Electromagnetic Location Schemes Relevant to Mine Rescue: Part I - Executive Summary; Part II - Collected Reprints - Analytical Investigations of Electromagnetic Location Schemes Relevant to Mine Rescue

- Cableless Electronic Surveying Systems for Horizontal Holes

- Comparison of Rotary and In-Hole Motor Techniques for Drilling Horizontal Boreholes in Coal

- Demonstration of Remote Mine Seal Construction

- Mine Rescue Training Facility Inventory - Compendium of Ideas to Improve US Coal Mine Rescue Training

- Mining Communications and Tracking

- Rapid Response Rescue Drilling System Development for Mine Rescue Application

- Refuge Alternatives in Underground Coal Mines

- Snake Robot for Mine Rescue

- Page last reviewed: 1/11/2017

- Page last updated: 11/28/2016

- Content source: National Institute for Occupational Safety and Health, Mining Program

ShareCompartir

ShareCompartir