Mining Feature: Dust Control Handbooks for Coal Mining and Metal/Nonmetal Mining

Friday, November 09, 2012

A pair of new handbooks from NIOSH, appropriately titled Best Practices for Dust Control in Coal Mining and Best Practices for Dust Control in Metal/Nonmetal Mining, were developed to identify and promote engineering controls to protect mine workers from overexposures to dust. The term “best practices” refers to methods that have consistently shown superior results compared to other options. Best practices are tried and true measures grounded in research and experience that represent what, how, and why something should be done. The best practices discussed in these handbooks are proven and effective controls to lower workers’ exposure to respirable dust and other airborne contaminants, such as diesel particulate matter.

Water Separator

Researchers from NIOSH Mining have spent decades investigating those best practices that will keep harmful dust from reaching the lungs of mine workers. In mining, overexposure to respirable dust can lead to disabling lung disease that can be fatal in its most severe form. According to NIOSH surveillance data, during 1970–2007, coal workers’ pneumoconiosis (CWP) was identified as a direct or contributing cause of 71,718 deaths of U.S. underground coal mine workers. Despite exposure limits established and enforced by the Mine Safety and Health Administration (MSHA), dust sampling requirements for both federal inspectors and mine operators, and ongoing surveillance programs, health problems related to dust overexposure remain a serious concern, with mining machine operators often at the highest risk.

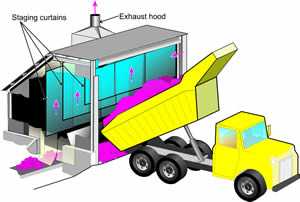

Among the engineering controls discussed in Best Practices for Dust Control in Coal Mining are the optimal locations for and use of dust samplers in mines, ventilation and spraying practices that reduce or eliminate dust as the coal is being cut, and effective cleaning and wetting of conveyor belts that transport the coal out of the mine. In the handbook, Best Practices for Dust Control in Metal/Nonmetal Mining, similar best practices are offered, but tailored to the fact that greater or different types of dust exposures can occur because of the percentage of silica in the specific product being mined or processed. Therefore, this handbook stresses the design of filtration and pressurization systems in mobile cabs designed to protect the cab operator, the use of booster fans to improve local ventilation, the installation of plastic stripping and curtains to reduce dust billowing during loading or unloading of product, and semi-automated or fully automated systems for loading bags of product onto pallets.

Staging Curtains

Key to best practices are effective maintenance activities, so both handbooks outline steps that mine operators can take to ensure sound maintenance of engineering controls. These include regularly inspecting for and replacing damaged components, maintaining good housekeeping practices that take advantage of design components, and ensuring the purity of water sprays to eliminate the possibility of sediment and debris clogging in spray nozzles. As the handbooks are updated in future years, NIOSH Mining researchers will continue to explore the best engineering controls and best maintenance activities available to protect mine workers from dust overexposure.

See Also

- Best Practices for Dust Control in Coal Mining

- Best Practices for Dust Control in Metal/Nonmetal Mining

- Dust Control Handbook for Industrial Minerals Mining and Processing

- Evaluation of the Approach to Respirable Quartz Exposure Control in U.S. Coal Mines

- Historical Mine Disasters

- NIOSH Mine Fire Research in the United States

- Risk Profile of Cumulative Trauma Disorders of the Arm and Hand in the U.S. Mining Industry

- Silica Dust Control for Metal/Nonmetal Mining

- Silica Dust Sources in Underground Metal/Nonmetal Mines - Two Case Studies

- Technology News 447 - Dust Collector Discharge Shroud Reduces Dust Exposure to Drill Operators at Surface Coal Mines

- Technology News 491 - NIOSH Releases Two New Safety Training Videos

- Technology News 501 - Measuring Very Low Air Velocities in Underground Metal/Nonmetal Mines

- Page last reviewed: 5/11/2016

- Page last updated: 11/9/2012

- Content source: National Institute for Occupational Safety and Health, Mining Program

ShareCompartir

ShareCompartir