Systems Approach to Design

Mining machines continue to grow in sophistication and performance. Regulatory requirements also have had to be incorporated into the design, further adding to the machine's complexity. This added complexity means that the burden of operating and maintaining the equipment has increased.

To cope with the mounting sophistication, many designers and manufacturers have turned to the "Systems Approach" for designing new hardware. Described below is an overview of one notion to the systems approach to design and how human factors engineering fits into it. We have taken the approach from previous work done on maintainability design for underground mining equipment. (1)

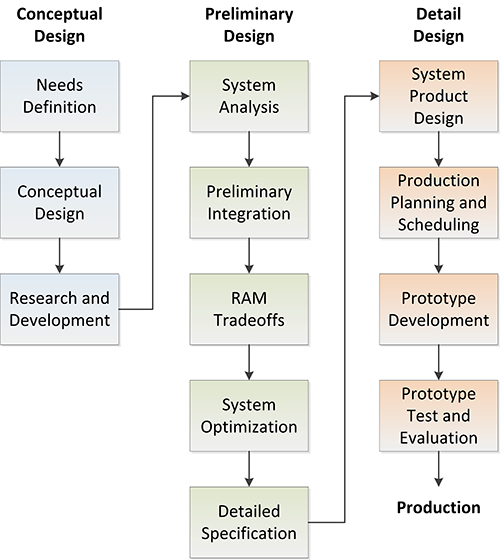

Designing a system is a fluid process. That is, the procedure itself has to be adapted to the situation in which it is being applied. The emphasis placed on each step in the design process presented below may change. However, you should include all of the steps discussed as part of the overall design process. The chart below illustrates one method of the Systems Approach to Design.

Conceptual Design Phase

During Conceptual Design, the initial concept for the new machine or system is defined. User needs and performance requirements are identified, preliminary research and development efforts initiated, and the system is specified. The product of this phase is a set of preliminary system specifications.

Needs Definition

Under the Systems Approach to Design, efforts are made to identify all user needs and requirements, equipment performance specifications, regulatory constraints, market conditions, and other factors impacting the system's performance before the formal design process is initiated. These factors may include:

- User production or performance requirements or standards.

- Cost considerations.

- Production and delivery schedules.

- Manufacturing costs.

- Federal, State, and local regulations.

- Industry standards and practices.

- Component or materials availability.

- Sales potential and current market conditions.

- Operator training and safety requirements.

- Maintenance requirements.

- Field support considerations.

- Research required for the application of new technologies, materials, procedures, or components.

The needs defined during this period provide the foundation for the conceptual design of the new machine.

Early Research And Development

During the Conceptual Design Phase, designers may initiate focused research efforts to identify ways to reduce costs, improve the design, or enhance productivity. This research may address the use of new materials, better fabrication techniques or design innovations, use of emerging technologies, analysis of competitor products, and similar topics. Often, market research is conducted to quantify the potential market for the new products or features. Outputs from this phase include updated engineering practices and technologies to be incorporated into the new product.

Conceptual Design

When needs have been defined and initial research completed, an early conceptual design of the machine is developed. This process permits the engineers to integrate user requirements with available technology. It also allows development of an overview of what the system may look like prior to hard tradeoffs that must be made later. The conceptual design step output may take the form of a series of functional specifications along with a description of the machine. The conceptual design and related supporting materials will often serve as the basis for project go/no-go decisions.

Questions To Ask During the Conceptual Design Phase

The following are some questions you may want to consider as the design engineer during the Conceptual Design Phase of the equipment development process: (2)

- Why is this system or piece of equipment being sought? What mission is the system or equipment expected to fulfill? More particularly, what is this new equipment expected to do that existing equipment is not doing or is not doing well enough?

- How is the system or equipment going to fulfill its mission? What are the stages of the mission execution? What functions must be accomplished by the equipment at each stage?

- In what environments must the system or equipment function? What particular hazards will be present? What stresses or demands are likely to be placed on the system?

- Who will benefit by the systems operation? Who will use the system? What level of experience is possessed by operators and maintenance personnel? Are high maintenance areas simple and efficient to access?

- What are the major technological options? What alternative configurations are possible?

Preliminary Design Phase

The design team next moves into the Preliminary Design Phase. During this phase, overall system requirements are integrated with available technology to produce detailed specifications for the new system. The output is a set of working system specifications. The following tasks are generally completed at this time.

System Analysis

A system functional analysis is completed to develop detailed specifications for all subsystems and major components on the machine. These specifications may include flow rates, power requirements, speeds, capacities, life cycles, weight, size, and other design shaping factors. For a simplified hypothetical continuous miner, the functions specified may cover:

- Coal-cutting head design.

- Coal-gathering mechanism.

- Coal conveyance system design.

- Coal-loading or transfer functions.

- Vehicle tramming subsystem.

- Safety and environmental subsystems.

- Operator and maintainer interface.

Preliminary Integration

User and other requirements are integrated with the preliminary system specifications to produce the preliminary system design. This design will identify subsystems and components to be developed during the detailed design phase of the project. It will also serve to identify potential problem areas that must be addressed prior to finalizing the design.

Reliability, Availability, Maintainability (RAM) Tradeoffs

RAM design tradeoffs are conducted at this point in the design. The objective is to increase the mean-time-between-failure for all performance critical components on the machine. Component reliability is researched and the higher performance components specified. This is followed by a maintainability requirement assessment for the selected components. Little improvement in maintenance performance is gained by selecting a high reliability component that requires higher-than-normal servicing. Reliability-maintenance requirements tradeoffs are then made.

Other design tradeoffs must be made to permit expeditious management of maintenance requirements. Parts with high frequency of repair, for example, should be located in readily accessible locations on the machine. The component-machine interface must be improved to permit rapid installation. Low probability of failure parts may be located in less accessible points on the machine. A second analysis is then completed to ensure compliance with all buyer RAM specifications.

System Optimization

System Optimization consists of a series of higher order design tradeoffs intended to optimize overall system performance, cost, delivery schedules, and other factors. These tradeoffs are conducted to finalize the preliminary design of the machine so that detailed specifications can be developed. System optimization is typically conducted just prior to the "Design Freeze."

Detailed Specifications

The last step in the Preliminary Design Phase is the preparation of detailed system design and performance specifications. The specifications may include:

- Overall system design and configuration.

- Listing of all subsystems and major components.

- Detailed system and component performance specifications.

- Reliability, availability, and maintainability requirements and specifications.

- User training and other user support requirements.

- Manufacturing and delivery schedules.

Completion of Computer-Aided Design (CAD) and other support systems may be required to be completed prior to proceeding to the next phase.

Questions To Ask During the Preliminary Design Phase

The following are some questions you may want to consider as the design engineer during the Preliminary Design Phase of the equipment development process: (2)

- What functions should be assigned to the human operator(s) and support personnel? What conditions will impose peak task loads on the operator or operators? What conditions (e.g., long periods of inactivity, heat, cold) will tend to degrade operator performance? What pattern of decision making and action will occur at crucial mission stages?

- What information is required by operators (and support personnel) to fulfill their functions? What is the probable pattern of channels and flow rate for this information? In what form (i.e., code, format) will the information be most useful to the operator?

- How many humans are needed to operate and support the system under normal and peak load conditions? What special skills, capabilities, or attributes are needed for effective operator performance? What special training, if any, will be required? Is such training feasible? What resources will be required to implement the training?

- How should the assigned functions be distributed among operator and support personnel? How should the work stations be arranged? What instrumentation is required at each workstation? How should this instrumentation be laid out?

- What specific devices, tools, or controls are most appropriate to the tasks that the operator and support personnel will be required to do? What kinds of aids, guides, indicators, locks, interlocks, cover plates, etc., would be useful to facilitate correct actions and prevent operator errors? What means are available to allow quick recovery or to maintain the safety and integrity of the system in the event of operator error or failure?

Detail Design Phase

The Detail Design Phase includes completion of system or product design, production planning, prototype development, and final testing and evaluation. The output from this phase is a set of production-ready plans and specifications and usually a prototype system. The following functions are performed during this phase.

System or Product Design

Product design includes preparation of engineering drawings for the new system hardware, software, and supportware. Personnel may have to be familiarized with technologies, such as Computer-Aided Design Systems, to complete this step.

Production Planning and Scheduling

Production planning is generally completed at this time. Availability of production resources, customer delivery requirements, scheduling of vendor-supplied components, and related actions are included. The output is the final project timeline and delivery schedule.

Prototype Development

When a new or redesigned machine is being developed, fabrication of an engineering prototype or preproduction model may be warranted. This prototype, or mockup, can be used for final testing and preproduction evaluation. Prototypes are also useful in identifying operator or maintainer interface problems and in assessing proposed manufacturing techniques.

Prototype Testing and Evaluation

A carefully planned series of prototype tests and evaluations may be initiated at this point. These tests are designed to:

- Ensure that the system meets design specifications and performance criteria.

- Identify design or engineering problems prior to committing to production.

- Identify operator or maintainer interface problems.

- Identify manufacturing problems or cost underestimates.

- Complete last-minute design modifications.

Questions To Ask During the Detail Design Phase

The following are some questions you may want to consider as the design engineer during the Detail Design Phase of the equipment development process: (2)

- What options are available for eliminating, combining, or simplifying any of the instrumentation?

- What will be the effect, if any, on human performance, safety, or morale of any proposed changes in configuration or instrumentation?

- What safeguards, if any, are required to ensure adherence to the design plan and functional requirements of the system? What quality control procedures are required to ensure the validity of human factors considerations in the final product?

- By what means can testing and evaluation be made as realistic as possible in terms of the ultimate operator and support personnel and in terms of the operational conditions?

- What criteria of system and operator performance are logical in terms of the mission and functions assigned? What measurement procedures will yield data that are valid with respect to such criteria? What test instrumentation is required?

- What form of test design will yield unequivocal answers to questions of the effectiveness, operability, and maintainability of the system? What is the most economical way of implementing the test design required?

Production Phase

When the engineering evaluation is completed, the new system is turned over to manufacturing for production.

Important Things To Consider

For human factors design to be most effective, you should consider it to be an essential part of a good design, not as something separate. Human factors has the greatest impact when it is integrated into the total design process from start to finish (3).

Other important points to consider about human factors design are:

- Consider human factors implications at all stages of the design process, especially the early stages. All your design decisions are likely to have some implications for the equipment operators and maintenance personnel. It is not enough to only consider human factors in the final, Detail Design Stage, when all major design decisions have already been made.

- Discuss human factors with all who are concerned with or affected by a design. This includes the client's management and operating personnel. The comments of the potential equipment operators and maintenance personnel are particularly valuable.

- Make your human factors requirements part of the Conceptual Design specifications so that their inclusion is ensured. Make your requirements as specific as possible, or they may not be adequately considered. Also, make certain your human factors requirements are budgeted for (e.g., task analysis, user trials, etc.).

- You will find that few things are simple when doing human factors design. However, you must be sensitive to the fact that there are often limits that, if exceeded, will affect performance or safety. Most of your design decisions will involve compromises. If you find that an optimal human factors solution is not possible, be sure that you carefully consider the consequences as you compromise, especially if recommended limits are exceeded.

- Apply human factors data intelligently and with caution. When you apply any data, make sure that the data are applicable to the current problem. You should examine the origins and assumptions of any data.

- Mockups and prototype trials are important for confirmation of designs. If you use human factors information from the start, you are likely to obtain a better first approximation and ultimate design. However, using mockups, even simple ones, with representative users is valuable for confirming details of fit, reach, layout, etc.

- For more difficult problems, where a logical approach alone is insufficient or where the consequences of error are serious, obtain the help of a human factors specialist.

References

- Conway, E. J., and R. Unger. Maintainability Design of Underground Mining Equipment: Volume II-Maintainability Design Guidelines (contract J0145034, Vreuls Research Corp.). USBM OFR 39-91-V2, 1988, 181 pp.; NTIS PB 91-241893.

- Joint Army-Navy-Air Force Steering Committee. Human Engineering Guide to Equipment Design. John Wiley and Sons, 1972, 752 pp.

- Corlett, E. N., and T. S. Clark. The Ergonomics of Workspaces and Machines. Taylor & Francis Inc., 1995, 128 pp.

See Also

- Engineering Considerations and Selection Criteria for Proximity Warning Systems for Mining Operations

- Job Design: An Effective Strategy for Reducing Back Injuries

- Job Training Analysis: A Process for Quickly Developing a Roadmap for Teaching and Evaluating Job Skills

- A Method for Evaluating System Interactions in a Dynamic Work Environment

- Programmable Electronic Mining Systems: Best Practice Recommendations (In Nine Parts): Part 2: 2.1 System Safety

- Programmable Electronic Mining Systems: Best Practice Recommendations (In Nine Parts): Part 4: 3.0 Safety File

- Programmable Electronic Mining Systems: Best Practice Recommendations (In Nine Parts): Part 5: 4.0 Independent Functional Safety Assessment

- Programmable Electronic Mining Systems: Best Practice Recommendations (In Nine Parts): Part 8: 6.0 Safety File Guidance

- Task Analysis

- Toward a Typology of Dynamic and Hazardous Work Environments

- Page last reviewed: 10/5/2016

- Page last updated: 2/28/2013

- Content source: National Institute for Occupational Safety and Health, Mining Program

ShareCompartir

ShareCompartir