module list

ELEMENTS OF ERGONOMICS PROGRAMS

Step 4: Implement your Ergonomic Program

To implement an ergonomic program, begin by targeting easy to implement solutions that you identified in your earlier analyses.1 Remember that early successes can build confidence and experience for resolving more complex musculoskeletal disorder (MSD) problems.

Determine your control solution

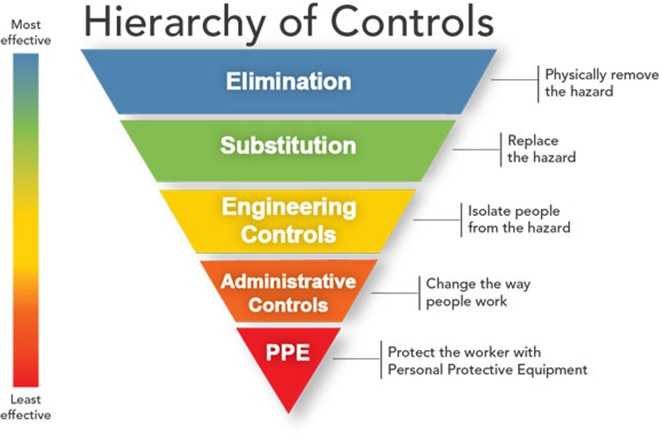

There are five approaches to control work-related musculoskeletal disorder (WMSD) risk factors. Elimination is the most effective way to reduce MSD risk factors in the workplace. The Hierarchy of Controls also includes substitution, engineering controls, administrative controls, and personal protective equipment. In ergonomics, engineering controls (isolating the hazard) lead to substitution (replacing the hazard) and/or elimination (removing the hazard). Personal protective equipment (PPE) and administrative controls are not as likely to reduce or eliminate WMSDs.

Figure 4.1: Hierarchy of Controls

Engineering controls are the most effective at reducing WMSD hazards, but may also be the most difficult to implement for an established work process. Change the way you use materials, parts, products, and tools and you can relieve workers from WMSD risks. Engineering controls include mechanical assist devices, fixtures, and lighter-weight packaging materials.

Administrative controls are practices and policies that workers must follow until engineering controls become feasible. You can reduce limit exposure to the hazard by reducing the length of workers’ shifts, implement a job rotation, schedule more breaks, vary the tasks for individual jobs, or train employees how to minimize exposure to hazard, such as stepping and turning instead of twisting during manual handling.

Personal protective equipment (PPE), such as knee pads and anti-vibration gloves and grip-gloves, may protect workers from immediate hazards. PPE is inexpensive and used frequently where hazards aren’t under administrative or engineering control. Learn more about the hierarchy of controls by visiting the NIOSH website.

Examples of Interventions

If you are unsure which intervention to use, you can find different interventions that may apply to your job task from several sources. Below are examples provided by the Ohio Bureau of Workers’ Compensation (BWC) for construction, extended-care, manufacturing, plastics and public industries.

- BWC Construction [PDF – 87 KB]

- BWC Extended-Care [PDF – 93 KB]

- BWC Manufacturing [PDF – 95 KB]

- BWC Plastics [PDF – 83 KB]

- BWC Public Employers [PDF – 97 KB]

Test your intervention

You can work with trade associations, workers compensation carrier companies, consultants and vendors, or other worksites to come up with the right ergonomic intervention for your WMSD problem. Once you have a good idea, you need to test if your proposed intervention will solve your WMSD problem.

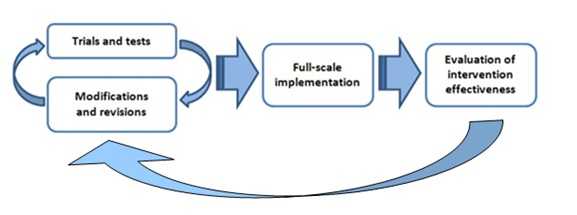

Figure 4.2: Intervention Process

The success of an intervention depends on workers’ acceptance of an idea. Try out the intervention in a limited manner and modify the proposed intervention as needed. Proceed to full-scale implementation when the pilot intervention is deemed successful.

Learn More on Hierarchy of Controls & Interventions:

[1]. Easy to implement requires high employee acceptance, management funding and easy to put into service.

- Page last reviewed: July 18, 2017

- Page last updated: August 22, 2017

- Content source:

- National Institute for Occupational Safety and Health Division of Applied Research and Technology

ShareCompartir

ShareCompartir