Respirator Trusted-Source Information

Section 3: Ancillary Respirator Information

The Basic FAQs

Who is NIOSH and what do they have to do with respirators?

The National Institute for Occupational Safety and Health (NIOSH) is the federal agency responsible for conducting research and making recommendations to prevent workplace injuries and illnesses. As part of the Centers for Disease Control and Prevention (CDC) within the Department of Health and Human Services (HHS), NIOSH helps assure safe and healthful working conditions by conducting scientific research, developing guidance and authoritative recommendations, disseminating information, and responding to requests for workplace health hazard evaluations.

The National Personal Protective Technology Laboratory (NPPTL) is the division within NIOSH responsible for the certification and approval of respirators for use in occupational settings, including those under the jurisdiction of the Occupational Safety and Health Administration (OSHA). This authority is implemented through regulations in Part 84 of Title 42 of the Code of Federal Regulations (42 CFR 84).

This NIOSH regulation defines the following authority:

- establish certain procedures and requirements, which manufacturers must meet when filing applications for NIOSH certification of newly developed respirators or modification to previously approved respirators;

- establish a schedule of fees charged to each applicant for inspections, examinations, and testing conducted by the Institute under the provisions 42 CFR 84;

- issue certificates of approval, or modifications to certificates of approval, for respirators which have met the applicable construction, performance, and respiratory protection requirements set forth in 42 CFR 84; and

- specify minimum requirements and to prescribe methods to be carried out by both the Institute and by the applicant in conducting inspections, examinations, and tests to determine the effectiveness of respirators used during entry into or escape from hazardous atmospheres.

What is a respirator?

A respirator is a personal protective device that is worn on the face, covers at least the nose and mouth, and is used to reduce the wearer’s risk of inhaling hazardous airborne particles (including dust particles and infectious agents), gases, or vapors. Respirators are considered as a “last line of defense” in the occupational hierarchy of controls. They are recommended when engineering and administrative controls are not feasible or sufficient to control the hazard, or until these other controls can be put in place.

Respirators protect the user in two basic ways; either by filtering contaminated ambient air or by providing a clean source of air. Respirators that remove contaminants from the air are called air-purifying respirators (APRs). APRs include particulate respirators, which filter out airborne particles, and “gas masks,” which remove gases and vapors from ambient air.

The classification of air-purifying respirators can be further subdivided into three categories:

- Filtering facepiece respirators (FFRs) – Sometimes referred to as disposable particulate respirators because the entire respirator is discarded when it becomes unsuitable for further use due to considerations of hygiene, excessive resistance, or physical damage. These are also commonly referred to as “N95s.”

- Elastomeric facepiece respirators – Sometimes referred to as reusable respirators because the facepiece is cleaned and reused while the filter cartridges and canisters are discarded and replaced when they become unsuitable for further use.

- Powered air-purifying respirators (PAPRs) – A battery-powered blower moves the air through the filters to the user.

The other type of respirators, which protect by supplying clean air from another source are called air-supplying respirators (ASRs). This type of respirator is comprised of airline, or supplied-air, respirators (SARs), which use compressed air from a remote source; and self-contained breathing apparatuses (SCBAs), which include their own breathing gas (compressed air or oxygen) supply.

What is an N95 respirator?

The NIOSH respiratory protection approval regulation (42 CFR 84) defines the term “N95” to refer to a filter class, not a respirator. However, many filtering facepiece respirators have an N95 class filter and many people refer to them, and have come to know them, as N95 respirators. A filtering facepiece respirator that filters out at least 95% of airborne particles during “worst case” testing using a “most-penetrating” sized particle is given a 95 rating.1 There are nine classes of NIOSH-approved particulate filtering respirators available at this time. 95% is the minimal level of filtration that will be approved by NIOSH. The N, R, and P designations refer to the filter’s oil resistance as described in the table below.

N95, N99, N100 – Filters at least 95%, 99%, 99.97% of airborne particles. Not resistant to oil.

R95, R99, R100 – Filters at least 95%, 99%, 99.97% of airborne particles. Somewhat resistant to oil.

P95, P99, P100 – Filters at least 95%, 99%, 99.97% of airborne particles. Strongly resistant to oil.

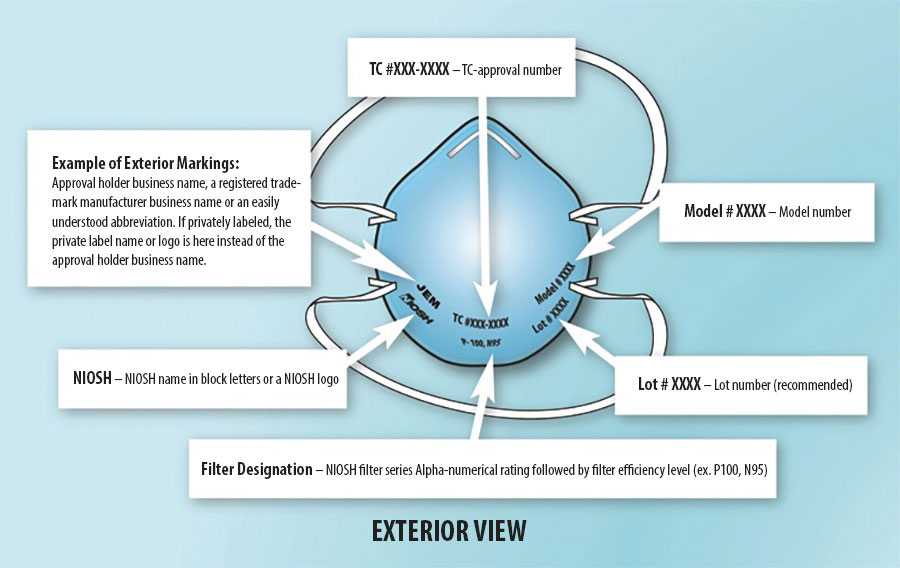

All NIOSH-approved filtering facepiece respirators are marked with the manufacturer’s name, the part number (P/N), the protection provided by the filter (e.g., N95, P100), and “NIOSH.” Some filtering facepiece respirators approved by NIOSH may have the NIOSH approval number (TC-84A-xxxx) as an additional identification marking. This information is printed either on the face, exhalation valve (if one exists), or head straps (see Figure 1). The lot number or date of manufacture may appear on the respirator or may be located on the packaging. View a listing of all NIOSH-approved particulate filtering facepiece respirators. NIOSH also maintains a separate database of all NIOSH-approved respirators, inclusive of all respirator types on the Certified Equipment List.

If a particulate filtering facepiece respirator does not have these markings as identified above and does not appear on one of these lists, it has not been certified by NIOSH for occupational use.

Figure 1. Example of typical markings on approved filtering facepiece respirators.

1 Reference: Rengasamy,S.,W.P.King, B.C.Eimer and R.E. Shaffer.(2008). Filtration performance of NIOSH-approved N95 and P100 filtering facepiece respirators against 4 to 30 nanometer-size nanoparticles. Journal of Occupational and Environmental Hygiene 5(9):556-564.

- Page last reviewed: October 12, 2017

- Page last updated: August 18, 2016

- Content source:

- National Institute for Occupational Safety and Health National Personal Protective Technology Laboratory

ShareCompartir

ShareCompartir