Volunteer Fire Fighter Killed When Pressurized Water Tank Explodes During Fire Suppression at a Brush Fire Ohio

Death in the Line of Duty...A summary of a NIOSH fire fighter fatality investigation

Death in the Line of Duty...A summary of a NIOSH fire fighter fatality investigation

F2010-32 Date Released: September 20, 2011

Executive Summary

On September 24, 2010, a 26-year-old male volunteer fire fighter (the victim) was killed when a pressurized 120-gallon water tank exploded during fire suppression activities at a brush fire. The water tank was mounted in the rear of the fire department's Humvee and was part of the department's portable pressurized water system used for brush and wildland fire suppression. The victim was standing near the rear of the Humvee watching fellow fire fighters put the system into operation when the tank exploded. The force of the explosion caused the base of the tank to separate from the tank and strike a motorized hose reel mounted at the rear of the Humvee's bed. The resultant force dislodged the hose reel which struck the victim, killing him instantly. A second fire fighter was knocked down by the force of the explosion and two other fire fighters narrowly escaped injury.

|

1986 Humvee was obtained by the fire department in 2009 through the state's surplus fire fighter property program. |

Contributing Factors

- Use of a self-made water delivery system without an over-pressurization safety relief or other safety mechanism and inappropriate system components

- Limited written operating procedures and policies

- The pressure gauge on the water delivery system was inappropriate for its intended use

- Limited training in the use of the equipment.

Key Recommendations

- Ensure that fire suppression equipment is properly designed and safe for its intended use and refrain from using self-made equipment that does not meet applicable safe design standards and practice

- Be aware of programs that provide assistance in obtaining alternative funding, such as grant funding, to replace or purchase fire apparatus and equipment.

|

Photo shows a rear view of the Humvee following the explosion. The water tank is seen in the center of the photo. Note that the bottom of the tank has completely separated from the rest of the tank. A motorized hose reel was mounted just in front of the tailgate. |

Introduction

On September 24, 2010, a 26-year-old male volunteer fire fighter (the victim) was killed when he was struck by a hose reel that had been dislodged from a fire apparatus by an exploding water tank. A second fire fighter was knocked down by the force of the explosion and two other fire fighters narrowly escaped injury. On September 27, 2010, the U.S. Fire Administration notified the National Institute for Occupational Safety and Health, Division of Safety Research, Fire Fighter Fatality Investigation and Prevention Program (FFFIPP) of the incident. That same day, the fire department was contacted by NIOSH investigators to initiate an investigation. On October 7, 2010, the NIOSH Fatality Investigation Team Chief, a safety engineer, traveled to Ohio to meet with representatives from several agencies investigating the incident including the sheriff's department, Ohio Bureau of Workers' Compensation, Ohio State Fire Marshal's office, and the insurance carrier for the municipality. The Team Chief inspected and photographed the vehicle and water delivery system. The Team Chief met with the department's Fire Chief during the site visit and made plans to continue the investigation.

On October 26, 2010, a safety engineer and an occupational health and safety specialist with the NIOSH FFFIPP traveled to Ohio to conduct a second inspection of the water delivery system. The NIOSH investigators met with the state fire marshal investigating the incident along with a representative from the county sheriff's office. Following this inspection, and with the consent of the fire department and other investigating parties, the NIOSH investigators took possession from the state fire marshal of the regulator, air hose, inlet valve, and the bottom "blown out portion" of the tank. The NIOSH investigators traveled to the fire department involved in the incident and met with the Fire Chief, a city solicitor, and fire fighters involved in the incident. The Fire Chief and fire fighters were interviewed. The NIOSH investigators obtained copies of the Humvee's maintenance and use records. The fire department did not have any written standard operating procedures (SOPs) or training requirements on the use and operation of the water delivery system. NIOSH investigators also spoke to the state's Agent for Surplus Property in Ohio regarding the history of the vehicle. NIOSH investigators spoke with the Fire Chief from another fire department in Ohio that had possession of the Humvee from 1996 to 2008, and had constructed the water delivery system, prior to returning the Humvee to the state surplus vehicle program. NIOSH contacted the manufacturer of the water storage tank to obtain specific information on the production, use, and failure criteria of the tank. The manufacturer and re-seller of the pressure regulator were also contacted.

The NIOSH FFFIPP contracted with a forensic test facility to test and evaluate the regulator used on the water delivery system. The findings from the regulator evaluation are summarized in this report. The full report is available upon request from the FFFIPP. NIOSH investigators contacted the manufacturers of both the water tank and the pressure regulator. Both manufacturers provided information on their respective manufacturing processes and quality assurance test requirements. The manufacturer of the pressure regulator was provided with a copy of the forensic test and evaluation report and provided comments on the report to NIOSH.

Fire Department

The volunteer fire department involved in this incident has 27 members including the Fire Chief, 2 assistant chiefs, 1 captain, 3 lieutenants, 1 safety officer and 1 training officer. The fire department operates from 1 station with a total of 5 apparatus including 3 Class A pumpers, 1 mini-pumper (330 gallon tank with a 750 gallon pump), 1 rescue vehicle and 1 hazardous materials (Haz-Mat) response trailer. The volunteer fire department provides fire and rescue services for a rural population of approximately 6,400 within an area of about 170 square miles consisting of a mixture of agricultural / farm lands, wildlands and small rural communities. The fire department responds to an average of about 160 calls per year including about 35 40 brush fires per year. The fire department does not provide emergency medical services. The fire department is rated as a Class 4 department by ISO.a In the ISO rating system, Class 1 represents exemplary fire protection, and Class 10 indicates that the area's fire-suppression program does not meet ISO's minimum criteria.

The fire department had limited written policies and procedures.

aThe Insurances Services Organization (ISO) is an independent commercial enterprise which helps customers identify and mitigate risk. ISO can provide communities with information on fire protection, water systems, other critical infrastructure, building codes, and natural and man-made catastrophes. ISO's Public Protection Criteria program evaluates communities according to a uniform set of criteria known as the Fire Suppression Rating Schedule (FSRS). More information about ISO and their Fire Suppression Rating Schedule can be found at the website http://www.isogov.com/about/.

Regulations and Guidelines

In the State of Ohio, specific safety requirements for fire fighting are found in Ohio Administrative Code (OAC), Chapter 4123:1-21. This code provides the minimum requirements for employers to protect employees and covers all regular members of lawfully constituted fire departments of municipal corporations and townships, whether paid or volunteer.1

The OAC, Chapter 4123: 1-21 covers topics such as personal protective clothing and equipment for structural fire fighting; personal protective clothing and equipment for wildland fire fighting; automotive fire apparatus; ground ladders; fire hose, couplings and nozzles; and fire department occupational safety and health. Chapter 4123:1-21-04 Automotive Fire Apparatus Section (J) lists construction requirements for water tanks mounted or attached to fire apparatus. Chapter 4123:1-21-07 covers fire department occupational safety and health.

Training and Experience

The fire department requires 36 hours of basic fire fighter training for an individual to be an active fire department member. New members must complete the required 36 hours of training and receive fire fighter certification from the State of Ohio within one year of joining the department. The State of Ohio also requires 18 hours of annual refresher training in order to maintain state certification. Fire department records showed that the department had offered a total of 43 hours of in-house training during 2010 up to the date of the incident. Most of this training involved hands-on-training with fire department equipment.

The victim had joined the fire department on August 18, 2010. He was scheduled to attend a 36-hour basic fire fighter training class in November 2010. On the day of the incident, other fire department members instructed the victim on basic brush fire tactics and procedures such as raking fire breaks.

According to the Fire Chief, the fire department required members to complete special hands-on training in order to operate the Humvee. The Humvee was a surplus military vehicle that was over-width so special training was required to operate the vehicle on a highway. The Humvee also required special starting procedures. The Fire Chief had to approve a member as being trained and qualified before that member could drive the Humvee. All training was hands-on at the fire department. The fire department records documented that two hands-on training sessions covering the operation and use of the water delivery system were held. The first training session was held on July 9, 2009 and a second training session was held on November 12, 2009.

Equipment

The vehicle involved in this incident was a surplus 1986 military model high mobility multi-purpose wheeled vehicle (HMMWV or Humvee). The vehicle was obtained by the fire department through the State of Ohio surplus property program on May 22, 2009. The fire department involved in this incident was the second fire department in Ohio to take possession of the Humvee. NIOSH investigators determined that the vehicle was first used as a fire department vehicle when another volunteer fire department in Ohio obtained two Humvees from the state's surplus vehicle program in December 1996. That fire department built the water delivery system in-house, installed it in the back of the Humvee involved in this incident, and put it into service in mid-1997. That fire department reported that the water delivery system was used 8-12 times per year through May 2008 when the vehicle was returned to the state surplus vehicle program. The department's other Humvee was used for other purposes and did not include a water delivery system. That fire department reported to NIOSH investigators that the Humvees became expendable after they had obtained funding to purchase a new brush truck, so both Humvees were returned to the state. The Humvee involved in this incident did not include seat belts.

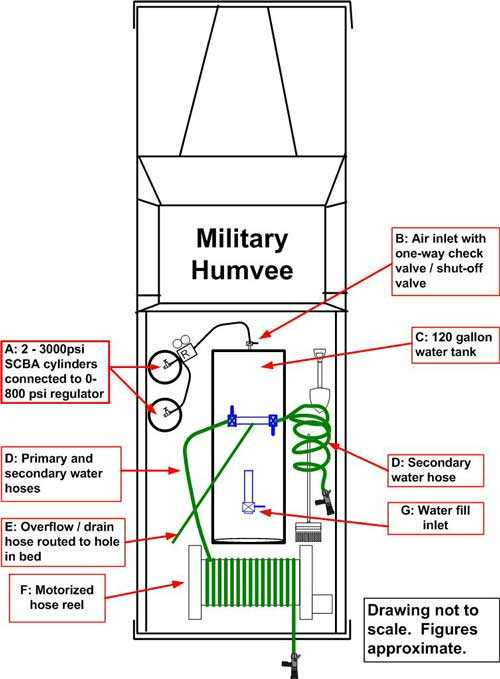

Table 1 and Diagram 1 describe the water delivery system. The system was an "air over water" delivery system. The system used air pressure, instead of a pump, to force the water from the tank and deliver it to hand-held hoses. The system used two standard 3,000 psi self-contained breathing apparatus (SCBA) air cylinders as the pressurized air source. Two standard CGA cylinder hand wheel connectors were connected in parallel with a ¼-inch high pressure hose to a pressure regulator. This allowed the system to be pressurized by either one or both SCBA cylinders. The fire department involved in this incident reported that when they took possession of the Humvee, they replaced the two SCBA cylinders with their own cylinders since they used a different brand of SCBA cylinder. Their procedure was to use one cylinder at a time, with the second cylinder in reserve.

The pressure regulator manufacturer determined for NIOSH that the regulator was produced in 2001. The regulator was a non-venting type regulator rated for a maximum inlet pressure of 6,000 psi and a field-adjustable outlet pressure of up to 1,800 psi. The regulator was sold without gauges or other hardware attached, to a vendor of pneumatic tool kits commonly used by fire departments. At some point, an aluminum spacer ring was added between the hand control knob and the regulator body to limit the outlet pressure. When NIOSH investigators obtained the regulator, the regulator was labeled with a maximum inlet pressure of 6,000 psi and a maximum outlet pressure of 300 psi. The regulator inlet was equipped with a pressure gauge graduated from zero to 5,000 psi and the regulator outlet was equipped with a pressure gauge graduated from zero to 800 psi (see Photo 1). Note: The SCBA cylinders and the pressure regulator are the critical parts needed to operate the system, and also the most expensive. When the fire department that originally constructed the system returned the Humvee to the state surplus property program, they removed their pressure regulator and SCBA cylinders. When the fire department involved in this incident obtained the Humvee, they had to add their own pressure regulator and cylinders in order to make the system functional. The first fire department used a different brand of pressure gauge that included a pressure relief valve (see Photo 2).

The regulated air was delivered from the pressure regulator to the tank through a 3/8-inch pneumatic hose of the type commonly used on air brake systems. The hose was labeled SAE J844 Type B and believed to be rated for 250 psi working pressure. The fire department reported that their procedure was to regulate the delivery pressure to the tank between 30 and 50 psi. The outlet pressure gauge was graduated in 25 psi increments from zero to 800. This would require the user to adjust the regulator so that the indicator needle was between the first two tics on the gauge scale to obtain the desired outlet pressure (see Photo 3). The pressurized air was delivered to the tank inlet through a one-way check valve and a ¼-inch 3-way shut-off valve. One side of the shut-off valve was plugged off so the valve acted as an "on-off" valve to isolate the tank and prevent water from flowing back into the regulator (see Photo 4).

The air pressure inside the tank forced the water through a 1½-inch copper pipe to an outlet at the top of the tank. The outside of the tank was fitted with a manifold constructed of a combination of various soldered copper pipe connectors and threaded pipe connectors. The manifold had two quarter-turn shut-off valves that controlled water flowing to two separate hoses (see Diagram 1). The primary hose (located on the driver's side) was attached to a motorized hose reel that was bolted to the bed of the Humvee just in front of the tail gate. The secondary hose (located on the passenger side) was loosely coiled in the bed of the Humvee. The manifold also included a drain hose that delivered overflow through a hole in the Humvee's bed near the rear of the Humvee and behind the wheels (see Diagram 1). All three hoses were heavy-duty 5/8-inch garden hoses.

The water tank could be filled from multiple sources through an inlet valve on top of the tank near the rear of the vehicle.

Table 1 – Water Delivery System Components

|

Item

( refer to Diagram1) |

Description |

|---|---|

A |

2 3,000 psi air cylinders served as the air source to pressurize the system. Air pressure was regulated with a non-vented pneumatic pressure regulator equipped with an 0 5,000 psi inlet and 0 800 psi outlet gauges. |

B |

Compressed air was delivered into the water tank through a 3/8-inch air brake hose to a ¼-inch pipe inlet with a one-way check valve and a three-way shut-off valve that had one side plugged. |

C |

120 gallon galvanized metal water tank rated for 75 psi internal pressure |

D |

Water was delivered to two water hoses thru a manifold system made from a combination of 1 ½-inch galvanized metal pipe fittings and soldered copper pipe fittings |

E |

Overflow / drain hose used to direct overflow underneath bed |

F |

The primary water hose was attached to a motorized hose reel that the fire department added in July 2009 after obtaining the Humvee in May 2009 |

G |

Water inlet – able to fill tank from multiple sources |

|

Diagram 1. Water Delivery System. |

|

|

Photo 1 (left) and Photo 2 (right). Photo 1 is the regulator used at the time of the incident. Photo 2 was reported to be the regulator used by the fire department who originally constructed the water delivery system.

|

|

|

|

Photo 3 (left) and Photo 4 (right). Photo 3 shows a close-up of the regulator outlet pressure gauge that is graduated in 25 psi increments. Photo 4 shows the one-way check valve and shut-off valve used at the inlet to the water tank. |

|

When the fire department involved in this incident obtained the Humvee in 2009 from the state's surplus vehicle program, it was dedicated for use at wildland / brush and grass fires. The Humvee and water delivery system provided the fire department with the ability to deploy water at remote and rough terrain areas that engines and mini-pumpers could not access. Fire department records showed that the first time the water delivery system was used was September 8, 2009. Records showed the Humvee was put in service 15 times including at 2 parades.

Water tank design and manufacture

The tank manufacturer reported to NIOSH investigators that the tank was designed as a hydro-pneumatic water storage tank for use in a home water well system. The tank's labeling stated it was designed to be used with ambient temperature water at a maximum pressure of 75 PSI. The tank was designed to be used in a vertical or up-right position but the tank was insensitive to position so mounting the tank in a horizontal position would not affect its performance (see Photo 5). The manufacturer reported that the tank was produced by rolling a sheet of steel into a cylinder and welding the edges together. Two tank heads were inserted into the ends of the cylinder and welded. The whole assembly, with various pipe connections welded in place, was then hot-dip galvanized. The bottom head was concave when installed and designed to fail at around 225 PSIG (failure being defined as a permanent deformation of the tank as opposed to tank rupture see Photo 6).

|

|

Photo 5 (left) and Photo 6 (right). Photo 5 shows the location of the 120-gallon water tank mounted horizontally in the bed of the Humvee. Note that the tank moved forward after the explosion. Photo 6 shows a close-up of the tank's bottom which separated. |

|

The tank's labeling stated "Any use in excess of these maximum conditions IS UNSAFE!!" and "A pressure relief valve of adequate size must be incorporated into the system" (see Photo 7). According to the manufacturer, the tank is not supplied with a pressure relief valve because pressure relief valves are extremely application sensitive.

|

Photo 7. Photo shows warning label attached to 120-gallon water tank. The label states “Max Work Pressure 75 PSI,” “Any use in excess of these maximum conditions IS UNSAFE!!” and “A pressure relief valve of adequate size must be incorporated into the system.” |

Following the incident, inspections of the water delivery system showed that the system did not include a pressure relief valve or device that would relieve excess pressure to prevent the system from being over-pressurized. The fire department stated that their belief was that a pressure relief device was present. There was no explanation for why a pressure relief valve or device was not present during the post-incident inspections. The water tank did not contain any baffles or swash partitions; it was designed for a stationary application and not intended for mobile applications. The tank was otherwise in good condition and did not show evidence of corrosion, rust, pitting or obvious signs of deterioration. The tank was not tested as part of this investigation.

Forensic evaluation and testing of the pressure regulator

NIOSH contracted with a forensic test facility to evaluate the performance of the regulator by measuring the outlet pressure in the "as-received" condition and then adjusting the regulator to measure the outlet pressure across the outlet pressure gauge scale. The forensic test facility pressurized the regulator and the supply pressure was slowly increased. It was observed that as the supply pressure was increased, the outlet pressure also increased. In other words, the regulator was not restricting or regulating the outlet pressure. The supply pressure was increased to 635 psi and the regulator outlet pressure (as measured by the regulator's output pressure gauge) was recorded at approximately 630 psi. After adjusting the regulator a number of times, it was clear that the regulator "as received" was passing supply pressure through the regulator to the outlet. The forensic test lab contacted NIOSH and it was decided that the regulator should be disassembled to try and identify the cause of the regulator failure.

The regulator was disassembled and no major problems were identified. The interior of the regulator had a white film that appeared to be consistent with a spray-on dry lubricant. The seat retainer, seat and valve were also removed from the body of the regulator. A few small white particles were observed loose on the inlet side of the seat. The forensic test lab theorized that these particles could have lodged between the seat and valve, preventing the valve from closing fully, allowing air from the supply inlet to pass through the regulator. The regulator manufacturer reported that a spray-on dry film lubricant was not used in the production of this regulator series. The regulator manufacturer stated that the white film could have been from the media used or could have been an oxide from the aluminum stock. A small distortion of the valve pin was also noted, but this did not appear to be significant enough to prevent the valve from operating.

The regulator was reassembled and pressurized. Initially, the regulator did not allow inlet pressure to pass into the outlet. When the regulator was adjusted as low as possible, air leaked through the regulator, pressurizing the outlet side of the regulator. The regulator control knob was rotated clockwise and the air flow through the regulator increased. The regulator control knob was rotated counterclockwise and the flow of air through the regulator decreased but did not stop.

Based upon the forensic evaluation and testing, a malfunction of the regulator prevented the regulator valve from closing completely. It could not be determined if this condition was present prior to the fatal incident or if it occurred as a result of the incident. It is noted that the water delivery system was used the day of the incident and appeared to be operating as expected up to the time of the incident.

Personal Protective Equipment

At the time of the incident, the victim was wearing structural fire fighting turnout pants, boots, a cotton tee-shirt and a helmet with goggles.

Weather Conditions and Terrain

At the time of the incident, the weather was overcast with an approximate temperature of 90°F and relative humidity of 29 percent. South-west winds were reported at approximately 20 23 miles per hour.2 The incident occurred in a rural area in an open field at the edge of a woodlot.

Investigation

A total of nine fire departments were dispatched at approximately 1400 hours for a large grass fire burning in a field in a rural location. The fire department involved in this incident provided mutual aid. This fire department responded with an assistant chief and two fire fighters (including the victim) on Engine 2403, one fire fighter driving the Humvee (Engine 2405), and two fire fighters driving their personally-owned vehicles (POV).

After arriving on scene, the crew was assigned to an area that did not have good access to the fire line. Vehicles and fences blocked the path of the Humvee. The victim was paired up with another fire fighter and they proceeded, along with the assistant chief, to walk uphill to rake a fire break through a wooded area.

Since access to the wooded area was blocked, the rest of the crew drove the Humvee to another area where they used the pressurized water system to extinguish hot spots along the fire line. After emptying the 120-gallon water tank, they returned to Engine 2403 and refilled the water tank. One of the SCBA cylinders used to pressurize the water tank was nearly empty and was replaced at this time.

The fire fighters on foot encountered a fire fighter from another fire department who was watching to make sure the fire did not break over the hill. The victim and the fire fighter continued uphill while the assistant chief remained with the fire fighter from the other department. The victim and the fire fighter continued to rake the fire break and to beat out hot spots that they encountered as they advanced through the woods. After some time, a bulldozer cutting a fire break came through their area. After stopping to rest, they radioed their crew on the Humvee that they needed water to drink. The victim and fire fighter continued to rake the fire break to the top of a hill where they stopped to rest again. From the top of the hill, they could see the Humvee so they again radioed for water, then began walking downhill to meet the Humvee. After meeting the Humvee, they rode in the Humvee with the rest of the fire fighters to another location to extinguish hot spots along the edge of an open field where a large dead tree was burning.

The two fire fighters who had been raking the fire break rested in the Humvee while the other two fire fighters began to extinguish hot spots. While applying water to the dead tree, the hose snagged and then burst, spraying the fire fighter who was working the nozzle. The fire fighter who had been driving the Humvee ran to shut off the air pressure to the water tank. After closing the SCBA cylinder valve and the water tank inlet valve, the fire fighters removed the section of burst water hose. After repairing the water hose, the fire fighter working the nozzle attempted to put water on the tree but did not have adequate water pressure. The victim and the fire fighter who had been sitting in the Humvee got out of the vehicle to observe what was going on. Note: Fire fighters interviewed did not report any noises or physical changes to the water delivery system that would have indicated a problem.

The victim was standing at the rear of the Humvee near the center of the tailgate when the water tank exploded. The force of the explosion caused the bottom of the tank (closest to the rear end of the vehicle) to separate from the rest of the tank (see Photo 5 and Photo 8). The tank was pushed forward into the dashboard, breaking the pneumatic airlines and connections in multiple locations. The Humvee's front windshield was shattered (see Photo 9). The bottom of the water tank was propelled into the motorized hose reel. The force ripped the hose reel's mounting bolts through the Humvee's bed (see Photo 10). The hose reel struck the vehicle's tailgate and then flipped over the tailgate, striking the victim. The victim was thrown backward approximately 20 feet (see Photo 11 and Photo 12), and was killed instantly. The hose reel came to rest in close proximity to the victim (see Photo 13) while the end of the water tank was propelled into the woods (see Photo 11 ). The fire fighter who had been operating the hoseline nozzle was knocked down by the force of the explosion but was not seriously injured. Two other fire fighters narrowly escaped injury.

Cause of Death

According to the coroner's report, the victim's cause of death was listed as blunt force injuries of the head.

Contributing Factors

Occupational injuries and fatalities are often the result of one or more contributing factors or key events in a larger sequence of events that ultimately result in the injury or fatality. NIOSH investigators identified the following items as key contributing factors in this incident that ultimately led to the fatality:

- Use of a self-made water delivery system without an over-pressurization safety relief mechanism and inappropriate system components

- Limited written operating procedures and policies

- The pressure gauge on the water delivery system was inappropriate for its intended use

- Limited training in the use of the equipment.

Recommendations

Recommendation #1: Fire departments should ensure that fire suppression equipment is properly designed and safe for its intended use and refrain from using self-made equipment that does not meet applicable safe design standards and practice.

Discussion: The water delivery system involved in this incident had been assembled by members of a volunteer fire department using components that were never intended to be used in fire suppression equipment. It was passed on to the department involved in this incident along with the excess property Humvee. The system was not consistent with safety standards applicable to pressurized water systems, pressure vessels, and fire apparatus water tanks. Fabricating fire suppression equipment and apparatus in-house may be an attractive alternative to purchasing more expensive equipment from fire service manufacturers, especially in the case of small and volunteer departments with limited financial resources. Such department-made equipment may be a viable and safe alternative to commercially available equipment provided that the department has access to the specialized technical knowledge and expertise required to design and fabricate equipment that operates safely, and to develop safe operating procedures and training for the equipment.

The department-made system involved in this incident incorporated several components that posed potential hazards to fire fighters:

- Water was transported in an un-baffled water tank, originally designed and sold for use as a stationary water reservoir in a residential water supply system. While not a factor in this incident, un-baffled water tanks have historically been identified as contributing to fire apparatus crashes.3,4 NFPA 1906, Standard for Wildland Fire Apparatus specifies design methods to reduce the impact of sloshing liquids in partially loaded tanks on vehicle stability.5

- The tank was clearly labeled as having a maximum working pressure of 75 psi. Compressed air from 3,000 psi SCBA cylinders was used to pressurize the system. A non-venting pressure regulator rated for a maximum inlet pressure of 6,000 psi and an outlet pressure of 800 psi was used to control the inlet pressure to the tank at 30 to 50 psi. The discharge side pressure gauge was graduated from 0 to 800 psi in 25 psi increments. When the regulator was adjusted to deliver a safe operating pressure between 30 to 50 psi, the gauge pointer rested near zero between the first and second ticks on the gauge scale (Photo 4). ASME B40.100-2005 Pressure Gauges and Gauge Attachments,6 stipulates that “The pressure gauge selected should have a full-scale pressure such that the operating pressure occurs in the middle half of the gauge scale. The full-scale pressure gauge selected should be approximately 2 times the intended operating pressure.” The gauge should have had a range of 0-100 or 0-150 psi.

- Air from the SCBA cylinders was routed to the forward head of the tank through tubing, a check valve, and a manually operated 3-way valve with two of the valve ports blocked so that it operated as a one-way shutoff valve. Forensic examination of the regulator after the incident revealed a malfunction due to an unidentified source that rendered the regulator incapable of controlling the air pressure introduced into the tank. This could have allowed the air pressure to exceed the water tank’s safe capacity resulting in catastrophic rupture of the tank bottom. Incorporation of a properly sized pressure relief valve as recommended by the manufacturer’s warning label and as stipulated by the ASME Boiler and Pressure Vessel Code7 may have safely vented the excessive pressure, maintaining the tank pressure below the 225 psi failure point.

Had the appropriate technical knowledge and expertise been available during the design and fabrication of the system, the need to follow recommended design standards for pressurized tanks and systems may have been fully appreciated; the potential hazards associated with the an over-pressurized water tank may have been recognized; and appropriate system components could have been added to prevent the occurrence. In general, commercial manufacturers of fire apparatus and equipment maintain qualified and competent design staffs that have knowledge of applicable standards, are trained to follow safe design practice and are able to develop and produce written safe operating procedures for their equipment.

While the expense of procuring equipment from commercial fire apparatus manufacturers may be a significant obstacle for resource challenged departments, the need for specialized technical knowledge and design expertise should over-ride financial considerations when considering whether to fabricate department-made equipment.

Recommendation #2: Fire departments should be aware of programs that provide assistance in obtaining alternative funding, such as grant funding, to replace or purchase fire apparatus and equipment.

Discussion: While it is important that fire departments seek constant improvements and upgrades to their fire apparatus and equipment, some departments may not have the resources or programs to replace or upgrade their apparatus and equipment as often as they should. Alternative funding sources, such as federal grants, are available to purchase fire apparatus and equipment. Additionally, there are organizations that can assist fire departments in researching, requesting, and writing grant applications.

Federal Emergency Management Agency (FEMA), Assistance to Firefighters Grant Program

www.fema.gov/welcome-assistance-firefighters-grant-program (Link Updated 1/28/2013)

A program of the Federal Emergency Management Agency (FEMA), grants are awarded to fire departments to enhance their ability to protect the public and fire service personnel from fire and related hazards. Three types of grants are available: Assistance to Firefighters Grants (AFG), Staffing for Adequate Fire and Emergency Response Grants (SAFER), and Fire Prevention and Safety Grants (FP&S). This website provides easy access to information concerning a number of FEMA grants programs including grants to obtain critically needed equipment and gear and grants to help fire departments increase their number of trained fire fighters.

- Assistance to Fire Fighters Grants (AFG)

http://www.fema.gov/assistance-firefighters-grant (Link Updated 1/16/2013) - The primary goal of the Assistance to Firefighters Grants (AFG) is to meet the firefighting and emergency response needs of fire departments and nonaffiliated emergency medical service organizations. Since 2001, AFG has helped firefighters and other first responders to obtain critically needed equipment, protective gear, emergency vehicles, training, and other resources needed to protect the public and emergency personnel from fire and related hazards.

- Staffing For Adequate Fire & Emergency Response Grants (SAFER)

http://www.fema.gov/staffing-adequate-fire-emergency-response-grants (Link Updated 1/28/2013) - The Staffing for Adequate Fire and Emergency Response Grants (SAFER) was created to provide funding directly to fire departments and volunteer firefighter interest organizations in order to help them increase the number of trained, "front line" firefighters available in their communities. The goal of SAFER is to enhance the local fire departments' abilities to comply with staffing, response and operational standards established by the NFPA and OSHA (NFPA 1710 and/or NFPA 1720 and OSHA 1910.134). For additional information on NFPA 1710 and NFPA 1720, visit:

Rural & Volunteer Fire Assistance

http://www.fs.fed.us/fire/partners/vfa/

The US Forest Service, Volunteer Fire Assistance Program (VFA), formerly known as the Rural Community Fire Protection Program (RCFPP) can provide Federal financial, technical, and other assistance to State Foresters and other appropriate officials to organize, train, and equip fire departments in rural areas and rural communities to suppress fires. A rural community is defined as having 10,000 or less population.

The following non-governmental websites provide additional resources and information related to the various types of grants programs available to the fire service.

National Fire Protection Association (NFPA), Safer Act Grant

www.nfpa.org/codes-and-standards/standards-development-process/safer-act-grant (Link Updated 8/13/2013)

The NFPA provides all its standards, on-line, free-of-charge in read-only format, including NFPA 1710 Standard for the Organization and Deployment of Fire Suppression Operations, Emergency Medical Operations, and Special Operations to the Public by Career Fire Departments and NFPA 1720 Standard for the Organization and Deployment of Fire Suppression Operations, Emergency Medical Operations, and Special Operations to the Public by Volunteer Fire Departments and other online resources to assist fire departments with the grant application process.

National Volunteer Fire Council (NVFC), Grants & Funding

http://www.nvfc.org/hot-topics/grants-funding (Link updated 4/9/2013)

The NVFC provides an online resource center to assist departments in navigating the complexities of applying for federal grants. Since more requests are made for federal grants each year than there are funds available, it is extremely important to prepare the best grant application possible. This guide is designed to make the process less daunting and assist departments and their grant writers in preparing a competitive application for these important grant opportunities.

FireGrantsHelp.com

www.firegrantshelp.com

A non-governmental group, FireGrantsHelp's missionis to providefirefighters and departmentswith a comprehensive resource for grant information and assistance. FireGrantsHelp.com provides an extensive database of information on federal, state, local, and corporate grant opportunities for first responders.

Recommendation # 3: Standard setting organizations should consider developing design and test requirements for pressurized air-over-water delivery systems for wildland fire suppression operations.

Discussion: Pressurized water delivery systems such as the one involved in this incident may have widespread applications in wildland fire suppression and other fire fighting applications. Currently, the NFPA standards do not address this type of fire suppression equipment. The NFPA and other standard setting organizations should consider developing minimum design and test requirements for pressurized air-over-water delivery systems. Such standards would help to ensure the safety and reliability of this type of fire suppression equipment used by the fire service. The water delivery system involved in this incident was self-made by a fire department and attached to a Humvee that was obtained through the state’s surplus property program. Since the pressurized water system was not covered by an NFPA standard, there was no requirement for maintenance, inspection and testing of the equipment. NFPA 1911 applies to both NFPA 1901 and NFPA 1906 apparatus. This document provides annual inspection and testing of pump equipment. Since the self-made water pressure system was not commercially manufactured, there were no manufacturer recommendations for testing or inspection. NFPA does not currently have documents that address retrofitting vehicles to perform the function of wildland fire apparatus. In addition, NFPA does not currently have documents that address water delivery systems such as the “air over water” system involved in this incident.

Recommendation # 4: Fire departments should ensure that all vehicle retrofits are completed by a qualified source and that retrofits are designed and installed within the original manufacturer's specifications.

Discussion: In this incident, a 1986 military model high mobility multi-purpose wheeled vehicle (HMMWV or Humvee) was used as a platform to transport a self-made pressurized air-over water delivery system for fire suppression operations at wildland / brush fires. The vehicle was obtained by the fire department in 2009 through the state's surplus vehicle exchange program. The vehicle had previously been used by another fire department in the same state and when in that fire department's possession, that fire department added the self-made water delivery system. It was intended for off-road use at brush fires and other areas that standard fire apparatus could not access. Note: The vehicle involved in this incident did not have any impact upon the outcome.

NFPA 1912 Standard for Fire Apparatus Refurbishing8 excludes vehicles that are not designed for highway use and do not meet applicable federal vehicle safety standards. NFPA 1912 provides guidelines for ensuring that refurbished fire apparatus meet all applicable federal, state, and local regulations covering vehicle safety as well as the applicable NFPA standards covering fire apparatus.

It is important to understand how retrofitting vehicles can change the vehicle's weight, center of gravity, and other operating characteristics. Fire departments should be aware of resources such as the Roscommon Equipment Center, a cooperative program between the National Association of State Foresters and the Michigan Department of Natural Resources.9 Roscommon Equipment Center develops guidelines for local, state, and federal fire agencies to safety convert vehicles to wildland fire apparatus. The NIOSH Fire Fighter Fatality Investigation and Prevention Program has conducted a number of investigations involving surplus vehicles and fire suppression equipment manufactured by fire departments, including this incident.4, 10-11

Recommendation # 5: Fire departments should provide training on the safe operation of specialized vehicles.

Discussion: Fire fighters require considerable knowledge, skills and abilities in order to properly and safely operate fire apparatus. The NFPA 1500 Standard on Fire Department Occupational Safety and Health Program, 2007 Edition recommends in Chapter 6.2 that fire departments provide training to all operators of all types of motorized equipment they will be expected to operate.12 NFPA 1002 Standard for Fire Apparatus Driver/Operator Professional Qualifications, Chapter 5 lists the requisite knowledge and skills necessary to safely operate fire apparatus equipped with fire pumps.13 The NFPA standards do not address pressurized water delivery systems such as the one involved in this incident which was self-made by another fire department. The pressurized water delivery system was obtained by the fire department involved in this incident when the Humvee that the water delivery system was mounted on was obtained through the state's excess / surplus program for use in fighting brush fires in off-road situations. No written procedures or training materials were available with the vehicle that would have covered the operation of the vehicle or the water delivery system. The fire department did hold a number of hands-on training sessions to familiarize fire fighters with the water delivery system and the number of times that the Humvee was used by the fire department was documented. For situations such as this, it may be necessary for fire departments to seek the assistance of a technical consultant with specific knowledge in the type of equipment to be used so that safe operating procedures and training plans can be developed.

References

- Ohio Administrative Code [2003]. Specific Safety Requirements of the Bureau of Workers' Compensation, Division of Safety and Hygiene. Chapter 4123:1-21 Fire Fighting. Ohio Administrative Code (OAC) Safety Codes. Bureau of Workers Compensation: Columbus Ohio: Nov 1, 2003. https://www.bwc.ohio.gov/basics/guidedtour/generalinfo/ORCandOAC.asp#fire. Date accessed: November 09, 2010. (Link Updated 10/28/2013)

- Weather Underground [2010]. http://www.wunderground.com/history/airport/KLCK/2010/9/24/DailyHistory.html?req_city=Chillicothe&req_state=OH&req_statename=Ohio. Date accessed: November 9, 2010.

- USFA / FEMA [2003]. Safe operation of fire tankers. Emmitsburg, MD: U.S. Fire Administration. http://www.usfa.fema.gov/downloads/pdf/publications/fa-248.pdf. (Link Updated 1/9/2012) Date accessed: July 20, 2011.

- NIOSH [2011]. NIOSH Workplace Solutions: Preventing deaths and injuries of fire fighters operating modified excess/surplus vehicles. Cincinnati, OH: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH Publication No. 2011-125). http://www.cdc.gov/niosh/docs/wp-solutions/2011-125/pdfs/2011-125.pdf.

- NFPA [ 2009]. NFPA 1905: Standard for Wildland Fire Apparatus, 2006 Edition. Quincy, MA: National Fire Protection Association.

- ASME [2005]. ASME B40.100-2005 Pressure Gauges and Gauge Attachments. 2005 revision. The American Society of Mechanical Engineers. New York, New York.

- ASME [2010]. ASME Boiler and Pressure Vessel Code. 2010 revision. The American Society of Mechanical Engineers. New York, New York.

- NFPA [2006]. NFPA 1912: Standard for Fire Apparatus Refurbishing, 2006 Edition. Quincy, MA: National Fire Protection Association.

- REC [2009]. Guidelines for designing wildland fire engines. Roscommon Equipment Center (REC). http://www.roscommonequipmentcenter.com. Date accessed: September 17, 2010.

- NIOSH [2011]. Volunteer Fire Chief Killed When Rubber-Tracked Vehicle Overturns at Brush Fire Washington. Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, Morgantown, WV. FACE Report F2010-15. http://www.cdc.gov/niosh/fire/reports/face201015.html.

- NIOSH [2011]. Volunteer Fire Captain Dies from Injuries Received After a Brush Truck Undergoing Maintenance Strikes and Pins Him Against a Wall Indiana. Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, Morgantown, WV. FACE Report F2010-37. http://www.cdc.gov/niosh/fire/reports/face201037.html.

- NFPA [2007]. NFPA 1500: Standard on fire department occupational safety and health program. 2007 ed. Quincy, MA: National Fire Protection Association.

- NFPA [2009]. NFPA 1002: Standard for Fire Apparatus Driver/Operator Professional Qualifications, 2009 Edition. Quincy, MA: National Fire Protection Association.

Investigator Information

This incident was investigated by Paul Moore, Chief, Fatality Investigations Team, Timothy R. Merinar, Safety Engineer, and Stacy C. Wertman, Safety and Occupational Health Specialist, with the Fire Fighter Fatality Investigation and Prevention Program, Surveillance and Field Investigations Branch, Division of Safety Research, NIOSH located in Morgantown, WV. A subject matter expert review was conducted Kevin D. Quinn of the National Volunteer Fire Council. A technical review was also provided by the National Fire Protection Association, Public Fire Protection Division. This report was authored by Tim Merinar and Paul Moore.

Additional Information

Fire fighters may be at risk for crash-related injuries while operating excess and other surplus vehicles that have been modified for fire service use. The National Institute for Occupational Safety and Health (NIOSH) has summarized recommendations to prevent injuries and deaths while operating these types of vehicles. http://www.cdc.gov/niosh/docs/wp-solutions/2011-125/pdfs/2011-125.pdf.

Roscommon Equipment Center is a cooperative program between the National Association of State Foresters and the Michigan Department of Natural Resources. Roscommon Equipment Center develops guidelines for local, state, and federal fire agencies to safety convert vehicles to wildland fire apparatus. http://www.roscommonequipmentcenter.com/.

Disclaimer

Mention of any company or product does not constitute endorsement by the National Institute for Occupational Safety and Health (NIOSH). In addition, citations to Web sites external to NIOSH do not constitute NIOSH endorsement of the sponsoring organizations or their programs or products. Furthermore, NIOSH is not responsible for the content of these Web sites.

|

Photo 8. Photo shows remains of the water tank in the bed of the Humvee after the explosion. The bottom of the water tank separated and struck the hose reel, propelling the hose reel over the tailgate. The hose reel is believed to have struck and fatally injured the victim.

|

|

Photo 9. Photo shows how the explosion propelled the front end of the water tank against the Humvee’s dashboard. The force of the water tank impacting against the dashboard shattered the windshield.

|

|

Photo 10. Photo shows the bolt holes through the bed of the Humvee where the motorized hose reel was mounted. The force generated by the end of the exploding tank striking the hose reel ripped the hose reel mounting bolts through the Humvee’s bed. Ripped metal at the location of bolt holes indicated by the arrows.

|

|

Photo 11. Photo shows the location where the bottom end of the water tank came to rest after the explosion. The Humvee is seen in the background. The victim and the hose reel were found near the wood line.

|

|

Photo 12. Photo shows the location of the incident scene. Crews were working to extinguish hot spots burning on the dead tree when the water tank exploded. The victim was standing near the rear of the Humvee when the water tank exploded (location marked by arrow).

|

|

Photo 13. Photo shows the hose reel that was mounted in the bed of the Humvee. After the explosion, the hose reel was found approximately 20 feet behind the rear of the Humvee and in close proximity to the victim. |

|

The National Institute for Occupational Safety and Health (NIOSH), an institute within the Centers for Disease Control and Prevention (CDC), is the federal agency responsible for conducting research and making recommendations for the prevention of work-related injury and illness. In 1998, Congress appropriated funds to NIOSH to conduct a fire fighter initiative that resulted in the NIOSH Fire Fighter Fatality Investigation and Prevention Program which examines line-of-duty-deaths or on duty deaths of fire fighters to assist fire departments, fire fighters, the fire service and others to prevent similar fire fighter deaths in the future. The agency does not enforce compliance with State or Federal occupational safety and health standards and does not determine fault or assign blame. Participation of fire departments and individuals in NIOSH investigations is voluntary. Under its program, NIOSH investigators interview persons with knowledge of the incident who agree to be interviewed and review available records to develop a description of the conditions and circumstances leading to the death(s). Interviewees are not asked to sign sworn statements and interviews are not recorded. The agency's reports do not name the victim, the fire department or those interviewed. The NIOSH report's summary of the conditions and circumstances surrounding the fatality is intended to provide context to the agency's recommendations and is not intended to be definitive for purposes of determining any claim or benefit.

|

For further information, visit the program Web site at www.cdc.gov/niosh/fire or call toll free 1-800-CDC-INFO (1-800-232-4636).

This page was last updated on 10/06/2011.

- Page last reviewed: November 18, 2015

- Page last updated: October 15, 2014

- Content source:

- National Institute for Occupational Safety and Health Division of Safety Research

ShareCompartir

ShareCompartir