Equipment Operator Killed when Pinned to a Tree by an Excavator

New York Case Report 06NY010

Summary

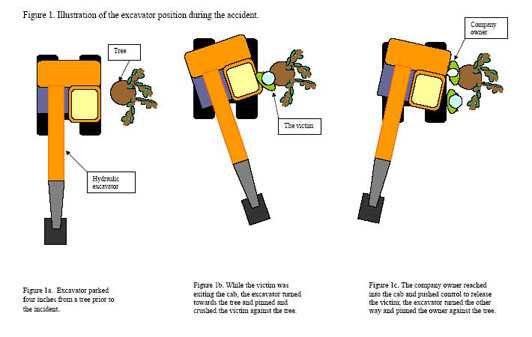

On February 21, 2006, a 47-year-old equipment operator, who was working for an excavating company, died after he was pinned to a tree by the cab of the hydraulic excavator he was operating (See Figure 1). At the time of the incident, the victim had been directed by the company owner to use the excavator to move dirt, clear debris, and fill a trench with sand at a residential building site. At approximately 1 p.m., the owner left the site for 20 minutes. When he came back, the owner saw that the excavator was parked over the trench and the victim had been pinned to the tree and crushed by the excavator. The excavator had a lock lever which locked the movements of the boom, arm, and excavating bucket as well as the swing function of the excavator; but the lock had not been activated. The owner immediately went to the other side of the tree, reached into the excavator and pushed the left joystick. Because the lock lever was not activated, the owner was able to turn the excavator to free the victim. As the excavator swung to free the victim, its cab pinned the owner to the other side of the tree. The owner yelled for help. Meanwhile, he was able to push the control to turn the excavator to free himself before other workers arrived. One worker called 911 and emergency medical services (EMS) arrived in minutes. The victim was pronounced dead at the scene. The owner suffered broken ribs and a punctured lung, and was taken by a helicopter to a hospital trauma center. He recovered and returned to work one month later.

New York State Fatality Assessment and Control Evaluation (NY FACE) investigators concluded that to help prevent similar incidents from occurring in the future, employers should:- ensure that equipment operators fully understand and strictly follow the safe operating procedures required by manufacturers including, but not limited to, lowering the excavator bucket to the ground and activating the swing lock before exiting the machine;

- conduct a job site survey during the planning phases of any construction project to identify potential hazards and develop and implement appropriate control measures to protect workers.

Additionally, excavator manufacturers should:

- designate an entire section or chapter to address safety precautions and safe operating procedures and ensure that the safety section of the operation and maintenance manual can catch readers' attention; and

- warn users of the potential hazards of not activating the lock lever.

Introduction

On February 21, 2006, a 47-year-old equipment operator died after he was pinned to a tree trunk by a hydraulic excavator. At the time of his death, the victim was working for an excavating company. NY FACE staff learned of the incident on February 22 through a newspaper article. On April 27, a NY FACE investigator met with the owner of the excavation company to collect information surrounding the incident and examined the excavator that was involved in the incident. The NY FACE investigator also met with a representative of the equipment manufacturer and discussed the case. The case was reviewed with the compliance officer who investigated the incident for the Occupational Safety and Health Administration (OSHA). The New York State Police incident report, medical examiner’s report, and death certificate were also reviewed.

The excavating company had been in business for 25 years. At the time of the incident, the owner had his son, the victim, and one other employee working at the site. The victim had his own blacktop business and was considered an experienced equipment operator. According to the owner of the excavation company, he and the victim were long time friends and frequently helped each other on jobs. This was the company’s first fatality.Back to Top

Investigation

At the time of the incident, the excavating company was working on vacant land to build a modular home. The project started in 2004 and the foundation was completed in November of 2005. On the day of the incident, the owner’s son, the other employee, the owner, and the victim were all working at the site. There was no inclement weather reported that day, nor were there treacherous ground conditions, such as ice, snow, mud or sloped surfaces. Prior to the incident, the owner’s son and the employee worked on the house while the owner and the victim cleared the land. According to the owner, it was the first time the victim had worked at the site. He was directed by the owner to use a hydraulic excavator (Photo 1) to move dirt, clear debris, and fill a trench with sand.

The owner purchased the excavator in 2000 from a local construction equipment dealer. The excavator was a 1990 model that weighed 12,000 pounds with an 84 horsepower motor. It had a boom with an articulating arm to which an excavating bucket was attached. The excavator could rotate 360 degrees with a swing speed up to 12.5 revolutions per minute (RPM). According to the owner, he had kept up with basic maintenance such as oil changes and lubrication. The machine had been operable the majority of the time since it was purchased. He did not have the victim review the excavator’s operation and maintenance manual.

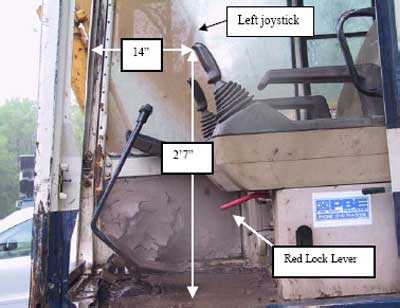

The excavator had one control lever (joystick) on each side of the driver seat: the joystick on the operator’s right side controlled the movements of the boom and the excavating bucket while the one on the operator’s left side by the cab door (Photo 2) controlled the arm movements and the excavator’s swing motions. The red lock lever under the driver’s seat on the left side had two positions: lock and unlock (Photo 3). When the lock lever was in the locked position, movements of the boom, the arm and the excavating bucket were disabled and the excavator would not rotate. As shown in Photo 2, the left control joystick was located approximately 2 feet 7 inches from the floor of the excavator’s cab. It extended from the left control console on the driver’s seat, reducing the cab door opening to 14-inches wide. The manufacturer specified in the operation and maintenance manual that the operator should always lower the excavating bucket to the ground and set the lock lever to the locked position when parking or leaving the machine to prevent inadvertent activation of machine parts.

|

|

Photo 3. The lock lever under the driver’s seat. There are two positions: unlock (up) and lock (down). |

At approximately 1 p.m., the owner left the site in his pickup truck to get sand for the victim to fill the trench. The owner came back approximately 20 minutes later and, from a distance, saw the excavator parked over the trench and the victim standing on the excavator treads next to a tree. As the owner got closer, he saw that the cab door was open and the victim pinned to the tree by the excavator. His back was facing the cab, as if he were exiting the cab. The excavating bucket had not been lowered to the ground and the lock lever had not been set in the locked position. The excavator was located approximately 6 inches from the tree. It appeared that when the victim was exiting the cab, he inadvertently bumped the left control joystick with his leg causing the excavator to rotate counter-clockwise and pin him against the tree (Figure 1).

The owner immediately went to the other side of the tree, reached into the excavator and pushed the left joystick. Because the lock lever was not activated, the owner was able to turn the excavator to free the victim. As the excavator swung to free the victim, it pinned the owner to the other side of the tree. The owner yelled for help. Meanwhile, he was able to push the joystick a second time, swinging the excavator away and freeing himself before his son and employee arrived. The employee called 911 and EMS arrived in minutes. The victim was pronounced dead at the scene. The owner was taken by a helicopter to a hospital trauma center, having suffered broken ribs and a punctured lung. He recovered and returned to work a month later.

Back to Top

Cause of Death

The cause of death was listed on the death certificate as asphyxia due to crush injury/ thoracic compression.

Back to Top

Recommendations/Discussion

Recommendation #1: Employers should ensure that equipment operators fully understand and strictly follow the safe operating procedures required by manufacturers including, but not limited to lowering the excavator bucket to the ground and activating the swing lock before exiting the machine.

Discussion: Prior to allowing a worker to operate an excavator, employers should ensure that the worker receives proper training. It is important that employers obtain and keep the operation and safety manuals from equipment manufacturers, and require operators to review the manuals and follow manufacturer’s instructions and requirements when operating the machine.

In this case, the manufacturer specified that an operator should always lower the excavating bucket to the ground and apply the swing lock when parking or leaving the machine. By following the manufacturer’s requirement, the inadvertent activation of the machine that caused the fatality could have been prevented.Recommendation #2: Employers should conduct a job site survey during the planning phases of any construction project to identify potential hazards and develop and implement appropriate control measures to protect workers.

Discussion: Before beginning work at any construction site, employers should have a competent person evaluate the site to identify any potential hazards and develop and implement appropriate control measures to protect workers. In this case, a planning stage survey may have identified that the tree may have been a safety hazard since it was too close to the location of the trench. If the employer had implemented proper control measures such as relocating the trench, warning workers about the potential hazards, and emphasizing the importance of following the manufacturer’s safe operating procedures, the tragedy may have been prevented.

Recommendation #3: Excavator manufacturers should ensure that the section of safe operating procedures and precautions stand out in the operation and maintenance manual to catch the readers' attention.

Discussion: In this case, the section of Safety and Operation containing safe operating procedures and precautions was not listed in the table of contents of the excavator operation and maintenance manual; although it was found at the end of the manual. The requirement of activating the swing lock when parking or leaving the machine first appeared in the manual on page 24; it was incorporated into the section of Instruments and Controls.

The safe operating procedures and warnings should be emphasized and clearly addressed in the manual in a format and language designed to capture the readers’ attention. The manufacturer may consider placing the Safety section at the beginning of the manual and clearly explain the hazards of not activating the swing lock.Recommendation #4: Excavator manufacturers should warn users of the potential hazards of not activating the lock lever.

Discussion:The newer model of the excavator has an extended swing lock lever (Photo 4) that blocks the cabin’s exit when it’s in the unlocked position (operating mode). The new model is more difficult for an operator to exit the excavator without setting the lock lever to the locked position (unblocking the exit). The lock lever of the older model that was involved in the fatal incident was low on the floor; an operator could easily step over it. The manufacturers should warn of the potential hazards associated with not activating the lock lever through their dealer network.

|

Photo 4. The lock bar in newer model excavators blocks the cab door path when in the unlock position. |

Keywords: machinery, excavator, swing lock, pinned and crushed.

References

CDC/NIOSH. Preventing Injuries When Working with Hydraulic Excavators and Backhoe Loaders. NIOSH Publication No. 2004-107. Retrieved on December 7, 2006 from

https://www.cdc.gov/niosh/docs/wp-solutions/2004-107/- DC/NIOSH. NIOSH FACE in-house Report # 2005-01:Hispanic Laborer Electrocuted When Crane Boom or Load Line Contacts 7,200 Volt Overhead Power Line – North Carolina. Retrieved on December 7, 2006 https://www.cdc.gov/niosh/face/in-house/full200501.html

New York FACE Program

The Fatality Assessment and Control (FACE) program is one of many workplace health and safety programs administered by the New York State Department of Health (NYS DOH). It is a research program designed to identify and study fatal occupational injuries. Under a cooperative agreement with the National Institute for Occupational Safety and Health (NIOSH), the NYS DOH FACE program collects information on occupational fatalities in New York State (excluding New York City) and targets specific types of fatalities for evaluation. NYS FACE investigators evaluate information from multiple sources. Findings are summarized in narrative reports that include recommendations for preventing similar events in the future. These recommendations are distributed to employers, workers, and other organizations interested in promoting workplace safety. The FACE program does not determine fault or legal liability associated with a fatal incident. Names of employers, victims and/or witnesses are not included in written investigative reports or other databases to protect the confidentiality of those who voluntarily participate in the program.

Additional information regarding the New York State FACE program can be obtained from:

New York State Department of Health FACE Program

Bureau of Occupational Health

Flanigan Square, Room 230

547 River Street

Troy, NY 12180

http://www.health.ny.gov/environmental/investigations/face/ (Link updated 4/8/2013)

Figures

|

- Page last reviewed: November 18, 2015

- Page last updated: October 15, 2014

- Content source:

- National Institute for Occupational Safety and Health Division of Safety Research

ShareCompartir

ShareCompartir