Hispanic Day Laborer Electrocuted When an Aluminum Extension Ladder Contacted an Overhead Power Line

New Jersey Case Report: 06NJ076

Report Date: March 19, 2009

Summary

On August 17, 2006, a 21-year-old Hispanic male day laborer was electrocuted when the aluminum extension ladder he and a co-worker were carrying in an upright position contacted a 13-kilovolt (KV) overhead power line. The ladder, missing a pulley to adjust the length, had been retrieved from a pile of damaged ladders at the general contractor's storage yard. The worker, an immigrant from Guatemala, had been on the job for three days. The incident occurred at a condominium complex where his employer, a subcontractor, had been contracted to remove and replace roofing shingles.

NJ FACE investigators recommend following these safety guidelines to prevent similar incidents:

- Employers should familiarize themselves with regulations and standards that govern safety and health in the workplace.

- Employers should develop and enforce a safety and health plan.

- Employers should conduct a site-specific job hazard analysis of all work activities.

- Employers should train workers on safe ways of working and recognizing and avoiding hazards.

- Employers should provide equipment to workers that are free of defects and are in good working condition.

Introduction

On August 25, 2006, the county medical examiner informed the NJ FACE project staff about the fatal work-related injury of a male Hispanic worker. The company foreman was contacted to obtain consent to participate in the NJ FACE project. Due to his limited english-speaking ability, his consent was obtained by a NJ Department of Health and Senior Services (NJDHSS) staff person who was fluent in Spanish. A site visit was conducted on September 8, 2006, accompanied by the NJDHSS interpreter. The project's "Informed Consent" form, translated into Spanish, was presented to the company foreman. Also present were the condominium property management officer and the board president. The incident site was viewed and photographed. The victim's co-worker was interviewed on September 12th at another location, with the NJDHSS Spanish interpreter present. Additional information about the incident was obtained from the police report, the medical examiner's report, and the OSHA investigation file.

The employer was a small construction company that performed siding, roofing, and carpentry work, and had been in business for less than two years. It was operated by one of the two co-owners, who owned 45% of the business. The second co-owner owned 55% of the company and held a valid certificate of insurance, but otherwise had no active involvement with the company. The company was incorporated, and operated under his certificate of insurance. The company was essentially run by a foreman (non-owner) who had been with the business for two to three months and who had previously owned his own construction business. Reportedly, he was paid a fee to obtain work and manage the jobs. NJ FACE staff had no communication with the co-owners, one of whom is no longer in the geographic area. The company had approximately eight workers at the time of the fatality. Training was on-the-job; there was no written training program, nor written safety policy or procedures. The workers, foreman, and company owners were fluent only in Spanish. The employer had been subcontracted by the general contractor to perform work on six residential condominium buildings, removing old roofing shingles and replacing them with new shingles. The job was to take approximately two weeks.

The victim, working as a day laborer, was a 21-year-old immigrant from Guatemala, possibly undocumented. There is no information on the length of time he had been in the United States and limited information on previous employment, although he may have had one year of experience in construction. The foreman knew the victim only by his first name; he was unaware of his surname. The victim's co-worker had been with the company for less than three months.

Back to Top

Investigation

The incident site was a two-story residential condominium complex of 300 units in 25 buildings, built between 1981 and 1986. The general contractor began replacing the roofing shingles in August, 2005.

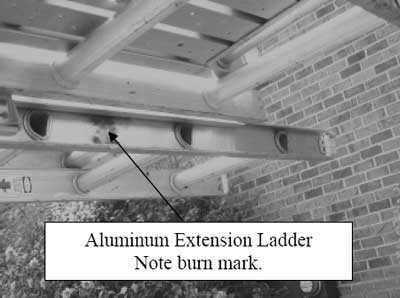

The workday began at 6:30 a.m. when the two employees picked up the company truck and equipment. The victim and his co-worker arrived at the condominium complex at 8 a.m. They worked from a list of items that the general contractor required to be completed, and spent the day replacing roofing shingles, accessing the work areas using ladders. By 3:20 p.m., the victim and his co-worker had only two corner overhangs on which they needed to apply finishing touches to complete the job, which they estimated would take one-half hour. The co-worker left to obtain additional materials. When he returned, the victim informed him that they needed to move the extension ladder that they had been using. The aluminum extension ladder could extend to 32 feet and had a maximum working length of 29 feet. It had been retrieved from a pile of damaged ladders at the general contractor's offsite storage yard. These ladders had been discarded, but the subcontractor's employees were apparently unaware of this. The foreman had previously told the workers to use the ladder in question only to reach scaffolding, which was no longer in place. Although the rung locks on the ladder worked, there was a rope, but no pulley, to adjust its length. The co-worker reported that he told the victim that they should shorten the ladder before moving it, but the victim replied that instead of shortening it he would carry it extended. The victim told his co-worker to support the ladder so it wouldn't fall. Although the co-worker said that he usually carried a ladder with it held parallel to the ground, this time they carried it while it was upright. Both were apparently unaware of the overhead power lines in the area. They walked approximately 24 feet when a slight wind caused the ladder to sway. The victim was walking backward, holding the ladder by the rungs while his co-worker walked forward holding onto the side rails.

|

The extended aluminum ladder contacted the 13-KV overhead power line, which was 25 feet above the ground. When it made contact, the co-worker reported that he heard a sound like thunder and saw fire come out of the power line. Both workers released the ladder and it fell to the ground. According to his co-worker, the victim was initially able to crawl, but not able to rise to his feet. Sparks ignited the dry grass at three small spots and the co-worker stomped out the fire. At the time of contact, the co-worker reported that he felt a shock that seemed to travel from his head down through his feet. Although his shoes were not damaged, he developed a dime-size burn on the arch of his right foot. One of the nearby residents reported hearing a boom and saw that her interior lights went out. She looked out a window and saw the victim lying on the ground with his co-worker trying to assist him. The resident called 911 and reported that emergency responders and paramedics arrived quickly to the scene. The victim was treated at the site and transported to the nearest hospital emergency department, where he was pronounced dead at 3:59 p.m., approximately one-half hour after the incident. The medical examiner reported that the worker had electrical burns on the sole of his right foot and toe of his left foot, and indistinct markings on his chest. Although he wore only frayed gardening-type gloves with rubberized palms, the medical examiner did not report burn marks on the victim's hands. The worker was survived by his girlfriend and his unborn baby.

|

The local power company responded to the site after the fatality to inspect the lines, investigate the incident, and repair the power line. Their report was not available.

Back to Top

Recommendations/Discussion

Recommendation #1: Employers should familiarize themselves with regulations and standards that govern safety and health in the workplace.

Discussion: Employers who are starting companies, or are new to the United States, should inform themselves about health and safety regulations set by the Federal Occupational Safety and Health Administration (OSHA), regulations pertaining to hiring and paying workers, and other standards that will assist with ensuring the safety and health of workers. This should be accomplished before beginning business operations. Information is available in languages other than English. Several of the resources listed in the Appendix are available in Spanish.

Recommendation #2: Employers should develop and enforce a safety and health plan.

Discussion: All companies involved in construction projects should have a safety and health plan. A safety and health plan encourages a culture of safety, and promotes employee awareness of the work environment, possible hazards, and safe work practices.

Accident prevention is the responsibility of the employer. Due to the failure to adhere to legally-required general safety and health responsibilities, OSHA cited the company under standards that address accident prevention responsibilities. Standard 29 CFR 1926.20 (b) (1) states that "It shall be the responsibility of the employer to initiate and maintain such programs as may be necessary to comply with this part" (general safety and health provisions). Standard 29 CFR 1926.20 (b) (2) states that "Such programs shall provide for frequent and regular inspections of the job sites, materials, and equipment to be made by competent persons designated by the employers."

Recommendation # 3: Employers should conduct a site-specific job hazard analysis of all work activities.

Discussion:To prevent incidents such as described in this report, NJ FACE recommends that employers conduct a site-specific job hazard analysis of all work areas and job tasks, with input from the employees. A job hazard analysis breaks down a job or task into specific steps, evaluates each task for hazards, and uses this information to develop safe ways of eliminating or reducing identified hazards. A job hazard analysis should begin by reviewing the work activities for which the employee is responsible and the equipment that is needed by the employee. Each task is further examined for mechanical, electrical, chemical, or any other hazard that the worker may encounter. The results of the analysis can be used to design a written standard operating procedure (SOP) for the job.

Failure to recognize hazards in the environment contributed to exposure to high-voltage electric current. The company was issued a citation for violating 29 CFR 1926.416 (a) (1), which states that "No employer shall permit an employee to work in such proximity to any part of an electric power circuit that the employee could contact the electric power circuit in the course of work, unless the employee is protected against electric shock by de-energizing the circuit and grounding it, or by guarding it effectively by insulation or other means."

Additional information is available in the publication, Job Hazard Analysis, which is available on the OSHA Web site at www.osha.gov/Publications/osha3071.pdf.

Recommendation #4: Employers should train workers on safe ways of working and recognizing and avoiding hazards.

Discussion: The workers were unaware of possible unsafe conditions in their work area. Although the overhead power line was more than 20 feet away from the work area, it became a hazard when the workers carried the ladder in an upright position. The fact that the victim and his co-worker did not recognize this to be a hazard suggests that they lacked understanding and training.

Training should be provided on the safe use of all equipment, including methods of using and carrying ladders. Training requirements are covered by the OSHA standard 29 CFR 1926.1060 (a), for which the company was issued a citation. This regulation states that "The employer shall provide a training program for each employee using ladders and stairways, as necessary. The program shall enable each employee to recognize hazards related to ladders and stairways, and shall train each employee in the procedures to be followed to minimize these hazards."

Recommendation #5: Employers should provide equipment to workers that are free of defects and are in good working condition.

Discussion: The employer was responsible for ensuring that all equipment, including the ladder, was free of defects and in good working order. The ladder used in this incident had been discarded by the general contractor because it was defective, but retrieved and used by the workers on this job. They had previously used the same ladder to access scaffolding. Had the ladder not been defective and difficult to adjust, the workers may not have carried it upright. For allowing use of defective equipment, Federal OSHA cited the employer under 29 CFR 1926.1053 (b) (16). This regulation states that "Portable ladders with structural defects, such as, but not limited to, broken or missing rungs, cleats, or steps, broken or split rails, corroded components, or other faulty or defective components, shall either be immediately marked in a manner that readily identifies them as defective, or tagged with "Do Not Use" or similar language, and shall be withdrawn from service until repaired."

Appendix

Recommended Resources

It is essential that employers obtain accurate information on health, safety, and applicable OSHA standards. NJ FACE recommends the following sources of information which can help both employers and employees:

U.S. Department of Labor, Occupational Safety & Health Administration (OSHA)

Federal OSHA will provide information on safety and health standards on request. OSHA has four area offices in New Jersey that cover the following counties:

Hunterdon, Middlesex, Somerset, Union, and Warren counties

Telephone: (732) 750-3270

Essex, Hudson, Morris, and Sussex counties

Telephone: (973) 263-1003

Bergen and Passaic counties

Telephone: (201) 288-1700

Atlantic, Burlington, Cape May, Camden, Cumberland, Gloucester, Mercer, Monmouth, Ocean, and Salem counties

Telephone: (856) 757-5181

Federal OSHA

Web site:https://www.osha.gov/

New Jersey Public Employees Occupational Safety and Health (PEOSH) Program

The PEOSH Act covers all NJ state, county, and municipal employees. Two state departments administer the act; the NJ Department of Labor and Workforce Development (NJDLWD), which investigates safety hazards, and the NJ Department of Health and Senior Services (NJDHSS), which investigates health hazards. PEOSH has information available that may also benefit private employers.

NJDLWD, Office of Public Employees Safety

Telephone: (609) 633-3896

Web site: http://lwd.dol.state.nj.us/lsse/employer/Public_Employees_OSH.html

NJDHSS, Public Employees Occupational Safety & Health Program

Telephone: (609) 984-1863

Web site: http://www.nj.gov/health/peosh

On-site Consultation for Public Employers

Telephone: (609) 984-1863(health) or (609) 633-2587(safety)

Web site: www.state.nj.us/health/eoh/peoshweb/peoshcon.htm

New Jersey Department of Labor and Workforce Development, Occupational Safety and Health On-Site Consultation Program

This program provides free advice to private businesses on improving safety and health in the workplace and complying with OSHA standards.

Telephone: (609) 984-0785

Web site:

http://lwd.dol.state.nj.us/labor/lsse/employer/

Occupational_Safety_and_Health_Onsite_Consultation_Program.html

New Jersey State Safety Council

The NJ State Safety Council provides a variety of courses on work-related safety. There is a charge for the seminars.

Telephone: (908) 272-7712.

Web site: http://www.njsafety.org

Internet Resources

Other useful internet sites for occupational safety and health information:

- CDC/NIOSH - https://www.cdc.gov/niosh/

- Employment Laws Assistance for Workers and Small Businesses - http://www.dol.gov/elaws/

- National Safety Council - http://www.nsc.org/Pages/Home.aspx (Link updated 8/14/2012)

- NJDHSS FACE reports - http://www.nj.gov/health/surv/face/index.shtml

- CDC/NIOSH FACE - https://www.cdc.gov/niosh/face/

Reference

- Job Hazard Analysis. US Department of Labor Publication # OSHA-3071, 1998 (revised). USDOL, OSHA/OICA Publications, PO Box 37535, Washington DC 20013-7535.

- Preventing Worker Deaths and Injuries from Contacting Overhead Power Lines with Metal Ladders. National Institute for Occupational Safety and Health (NIOSH) Publication

No. 2007-155. - Prevencion de muertes y lesions de trabajadores debido al contacto de las escaleras metalicas con los cables de tendido electrico. Instituto Nacional para la Seguridad y Salud Ocupacional (NIOSH) Publicacion No. 2007-155.

New Jersey FACE Program

Fatality Assessment and Control Evaluation (FACE) ProjectInvestigation #05-NJ-099

Staff members of the New Jersey Department of Health and Senior Services, Occupational Health Service, perform FACE investigations when there is a report of a targeted work-related fatal injury. The goal of FACE is to prevent fatal work-related injuries by studying the work environment, the worker, the task, the tools the worker was using, the energy exchange resulting in the fatal injury, and the role of management in controlling how these factors interact. FACE gathers information from multiple sources that may include interviews of employers, workers, and other investigators; examination of the fatality site and related equipment; and reviewing OSHA, police, and medical examiner reports, employer safety procedures, and training plans. The FACE program does not determine fault or place blame on employers or individual workers. Findings are summarized in narrative investigation reports that include recommendations for preventing similar events. All names and other identifiers are removed from FACE reports and other data to protect the confidentiality of those who participate in the program.

NIOSH-funded state-based FACE Programs include: California, Iowa, Kentucky, Massachusetts, Michigan, New Jersey, New York, Oregon, and Washington. Please visit the NJ FACE website at www.state.nj.us/health/eoh/survweb/face.htm or the CDC/NIOSH FACE website at www.cdc.gov/niosh/face for more information.

The NJ FACE Project is supported by Cooperative Agreement #1 U60 OH0345-01 from the Centers for Disease Control and Prevention (CDC). The contents of this report are solely the responsibility of the authors and do not necessarily represent the official views of the CDC.

To contact New Jersey State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site. Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.

New Jersey Case Reports

New Jersey Case Reports

- Page last reviewed: November 18, 2015

- Page last updated: October 15, 2014

- Content source:

- National Institute for Occupational Safety and Health Division of Safety Research

ShareCompartir

ShareCompartir