Hispanic Roofer Dies After 15-Foot Fall from a Roof - North Carolina

NIOSH In-house FACE Report 2003-03

February 12, 2003

Summary

On August 29, 2002, a 23-year-old male Hispanic roofer (the victim) died from injuries he sustained when he fell over the unprotected edge of a roof of an elementary school gymnasium to an asphalt walkway approximately 15 feet below. The victim was part of a seven-man roofing crew. He was last seen standing near the edge of the roof pulling up an additional length of power cord for the electric screw guns. No fall protection system was in place. A coworker standing nearby saw the victim fall over the edge. The foreman was working at ground level at the time of the incident and heard coworkers’ calls for help. He called 911 from his cell phone while coworkers and school personnel ran to help the victim. Emergency responders arrived within a few minutes, and on observing the severity of the victim’s head injury, called for a medical helicopter for transport. The medical helicopter was delayed due to weather problems. A military helicopter responded approximately 30 minutes after the incident and transported the victim to a regional trauma center where he was pronounced dead on arrival. NIOSH investigators concluded that, to help prevent similar occurrences, employers should

- develop, implement, and enforce a fall protection plan that protects workers against potential fall hazards and, at minimum, meets OSHA standards for fall protection

- conduct a site inspection before beginning roofing work to identify all potential hazards and take appropriate steps to ensure that identified hazards are eliminated or controlled before work activities begin

- provide all workers with retraining in the recognition and avoidance of unsafe conditions, including but not limited to recognition and avoidance of fall hazards, and in required safe work practices that apply to their work environments

|

|

Elementary School Where the Incident Occurred

|

Back to Top

Introduction

On August 29, 2002, a 23-year-old male Hispanic roofer (the victim) died from injuries he sustained when he fell over the unprotected edge of a roof of an elementary school gymnasium to an asphalt walkway approximately 15 feet below. On September 25, 2002, officials of the North Carolina Department of Labor (NCDOL) Division of Occupational Safety and Health (NCOSHA), notified the National Institute for Occupational Safety and Health (NIOSH), Division of Safety Research (DSR), of the incident. On October 25, 2002, a DSR occupational safety and health specialist met with the NCOSHA supervisor and the safety compliance officer who had investigated the incident to discuss the case and to review information collected and photographs taken during the course of the NCDOL investigation. The DSR investigator visited the site, interviewed the school principal, and took photographs. The official cause of death was obtained from the death certificate. The company’s project manager was interviewed by telephone on November 11, 2002.

The employer was a roofing contractor and had been in business for 38 years. The company had several roofing jobs in progress throughout the region and employed approximately 30 employees. The incident occurred at a public elementary school where the company had a seven-man crew working for over a 2- month period removing shingles, and laying ice and water shield before installing a new metal roof. The crew had been rotating between this job and others in the area.

The victim had moved from Mexico to the United States and had worked as a roofer for the company for 3 years before the incident. The victim’s primary language was Spanish, and according to the project manager, he spoke a little English but was not fluent. The crew’s foreman and one coworker spoke English, two coworkers spoke both English and Spanish, and two coworkers spoke only Spanish. According to the project manager, the company had a safety and health plan written in English that covered safe work practices and included a fall protection plan. The company used an interpreter at all safety meetings to communicate safety information in Spanish to employees who did not speak English. Because illiteracy is common in the company’s workforce, the company depends upon verbal communication. The interpreter routinely translates safety information into Spanish and provides explanations as needed to meet the understanding level of employees. During safety training sessions the interpreter translates information given in English into Spanish and speaks into a transmitter to Hispanic workers wearing earphones. This method allows English and Spanish speaking workers to receive the training simultaneously in the same room. Company documents indicate that training programs communicated in both Spanish and English were administered by the project manager since January 2002. The company employs an outside professional safety consultant who assists the project manager with the development of safety procedures and with training. Training is documented and these documents indicate that the victim participated in safety training which included fall protection training on July 26, 2002.

According to the project manager, day-to-day safety responsibilities were delegated to the site foreman who communicated with Hispanic workers through coworkers who spoke both Spanish and English. The site foreman had been with the company for 20 years and was an experienced roofer and foreman. According to the project manager, all workers on the incident site had been trained in fall protection procedures but none of them could explain why fall protection was not used on the day of the incident. The company has an experienced workforce with a 6.5-year turnover rate. This was the first fatality experienced by the company.

Back to Top

Investigation

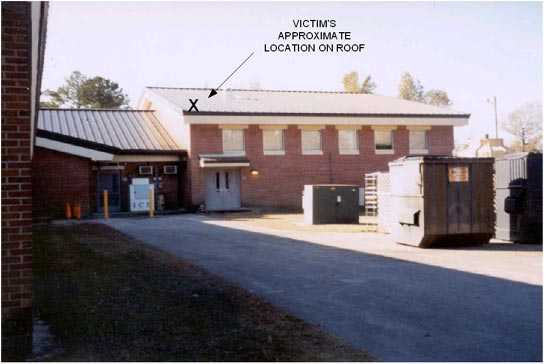

The employer had been contracted to remove shingles from the roof of an elementary school and to install a new metal roof (Photo 1). Work had been in progress for over 2 months and the seven-man crew had removed the old shingles and had put down a layer of ice and water shield. Ice and water shield is similar to heavy felt paper with an adhesive backing. It is layered and overlapped on the roof much like asphalt shingles to seal out moisture. The crew had returned to this job on the day of the incident after a lapse of several weeks. The work shift normally lasted approximately 10 hours starting at 7:30 a.m. and ending at 5 p.m.

|

| Photo 1. This photo illustrates the roof of the elementary school where work was being performed. An X marks the approximate location of the victim on the low-slope roof before his fall. |

On the day of the incident, work began at approximately 7:30 a.m. The crew spent the morning laying hat channel on the roof and tacking it in place. Hat channel are long, light-gauge metal members that are laid parallel to the roof line and roof edge. They are spaced every 5 feet and are screwed directly into the steel rafters or bar joists of the building. Roof panels are then secured to the hat channel. This system is used to ensure that the roof is adequately secured to keep it from being pulled off during high winds.

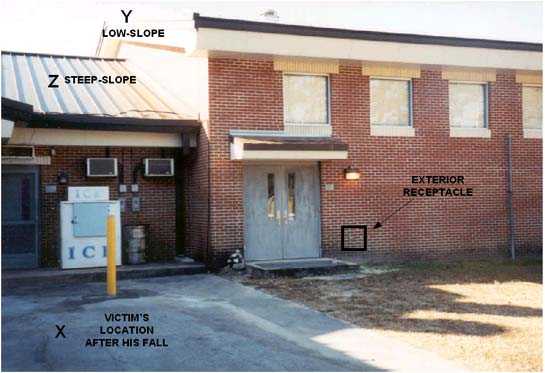

After lunch, the crew returned to the roof while their foreman worked at ground level. The victim was standing near the edge of the roof and began pulling up an additional length of electric power cord for the screw guns. The cord extended down over the edge of the roof and was plugged into an exterior receptacle next to the gymnasium entrance. The cord may have become entangled as the victim pulled it up near the gabled end of the roof. Evidence suggests that when the victim twisted his body to put leverage on the cord to free it, he lost his balance and fell backwards off the roof approximately 15 feet to the asphalt walkway below. A nearby coworker saw the victim fall over the edge of the roof (Photo 2). The foreman heard coworkers call for help and called 911 from his cell phone. Coworkers climbed down from the roof, and school personnel ran out of the building to help the victim. Emergency responders arrived within a few minutes, and observing the severity of the victim’s head injuries, immediately called for a medical helicopter. They provided emergency care including administration of intravenous fluids, wound care, and treatment for shock. The medical helicopter was delayed due to weather problems. A military helicopter responded approximately 30 minutes after the incident and transported the victim to a regional trauma center where he was pronounced dead on arrival.

|

| Photo 2. This photograph illustrates the approximate location of the victim following his fall, marked with an X. The photograph illustrates both a low-slope roof (marked with a Y) and a steep-slope roof (marked with a Z). OSHA regulations define low-slope and steep-slope roofs (29 CFR 1926.500). |

The project manager told the DSR investigator that everyone in the company was trained in fall protection and that a fall protection system was required for this job. For reasons that remain unclear, the crew did not use the fall protection system required by the company on the day of the incident. According to the project manager, the company’s fall protection plan for low-slope roofing work required the use of a safety warning line and a safety monitor. [Note: NCOSHA took measurements of the slope of the roof of the elementary school gymnasium. It was sloped 3 in 12 (vertical to horizontal)]. When workers moved outside the safety warning line and into the 6-foot space between the warning line and the roof edge, roofers were to be “tied off or under the watchful eye of a safety monitor.” On the day of the incident, the safety warning line was not in place, no employee had been assigned safety monitoring duties and the victim was not tied off.

Back to Top

Cause of Death

The death certificate indicated that the cause of death was cerebral contusions and basilar skull fracture.

Recommendations/Discussion

Recommendation 1: Employers should develop, implement, and enforce a fall protection plan that protects workers against potential fall hazards and, at minimum, meets OSHA standards for fall protection.

Discussion: The employer’s fall protection plan for the roofing work performed on the low-slope roof on the elementary school gymnasium, a combination of warning line system and safety monitoring system, was not used on the day of the incident—no warning line was installed and no employee was assigned safety monitoring duties. Employees on site were unable to provide OSHA investigators with a reason for the fall protection plan not being used. Employers should require daily inspections before the start of work to ensure that the fall protection system required by the company’s fall protection plan has been implemented.

In this incident workers were performing roofing on a low-slope roof* which was more than 50 feet wide. For guidance in developing fall protection programs that meet the employer’s duty to have fall protection, employers should refer to OSHA regulations found in 29 1926.501 Duty to have fall protection.1 OSHA requirements are addressed in 29 CFR 1926.501(b)(10) for roof work on low-slope roofs.

Individuals involved in roofing work on low-slope roofs must be protected when exposed to unprotected sides and edges 6 feet (1.8 m) or more above lower levels. This section gives several means of protection, one of which is a combination of a warning line system and safety monitoring system. According to an OSHA letter of interpretation dated July 23, 1996, “the warning line system is in place to protect those working within its perimeter, and only at the time when workers are required to go beyond this system would a monitor be needed to perform those functions listed in paragraph 29 CFR 1926.502(h)” [Search OSHA interpretations/letters at https://www.osha.gov/ using the term “warning line”].

The combination of a warning line system and safety monitoring system is only one of several fall protection systems that can be used on low-slope roofs. The others include guardrail systems, safety net systems, personal fall arrest systems (PFAS), or a combination of warning line system and guardrail system, warning line system and safety net system, or warning line system and PFAS. Employers should consider going beyond OSHA fall protection requirements for roofing on low-slope roofs and require the use of a fall protection system that has the capacity to stop a fall once it has begun. Examples of this would be a PFAS or a guard rail system.

The employer had been contracted to replace the entire roof of the elementary school, which had both low-slope and steep-slope roofs. Employers should ensure that the company’s fall protection plan also meets OSHA requirements addressed in 29 CFR 1926.501(11) for all roofing work performed on steep-slope roofs ( slope greater than 4 in 12) with unprotected sides and edges 6 feet (1.8 m) or more above lower levels. On steep-slope roofs employees must be protected from falling by guardrail systems with toeboards, safety net systems, or PFAS.

Recommendation #2: Employers should conduct a site inspection before beginning roofing work to identify all potential hazards and take appropriate steps to ensure that identified hazards are eliminated or controlled before work activities begin.

Discussion: To protect workers from falls, a “competent person”** should conduct a hazard assessment before starting work to identify fall hazards and eliminate or control them before work begins (e.g., provide an adequate fall protection system to prevent workers from falling over unprotected sides and edges of a working surface which is 6 feet or more above a lower level and ensure its use).

An inspection may have identified the placement of the power cord, which extended over the edge of the roof and plugged into an outlet near ground level, as hazardous. Workers were subject to fall hazards as they approached the roof edge to pull up additional lengths of entangled cord and to trip hazards as they walked on the roof using tools connected to the power cord. Had the inspection identified the potential hazard, a decision could have been made to use an alternative method for supplying power to tools, for example battery-operated tools, in this section of roof, thus eliminating the need for the power cord.

Recommendation #3: Employers should provide all workers with retraining in the recognition and avoidance of unsafe conditions2, including but not limited to, recognition and avoidance of fall hazards, and in required safe work practices that apply to their work environments.

Discussion: According to 29 CFR 1926.503(c)(3), employers should retrain employees when “inadequacies in an affected employee’s knowledge or use of fall protection systems or equipment indicate that the employee has not retained the requisite understanding or skill.” In this instance the fall protection system required by the company had not been used. According to OSHA 29 CFR 1926.503(a)(2), training is to be provided by a “competent person” qualified in the following areas:

- the nature of the fall hazards in the work area

- the correct procedures for erecting, maintaining, disassembling, and inspecting fall protection systems to be used

- the use and operation of guardrail system, PFAS, safety net system, warning lines systems, safety monitoring systems, controlled access zones, and other protections to be used

- the limitation on the use of mechanical equipment during the performance of roofing work on low-sloped roofs

- the correct procedures for handling and storage of equipment and materials

- the role of employees in the fall protection plans

- the applicable regulations contained in OSHA’s subpart M-Fall Protection (29 CFR 1926.500-503)3

For further information regarding OSHA regulations, see the OSHA web site at https://www.osha.gov/ .4 Additional information pertaining to worker deaths by falls from elevation is contained in a NIOSH publication on this topic (DHHS, NIOSH Publication No. 2000-116).5 This publication is available through NIOSH by calling 1 (800) 356-4674 or by visiting the NIOSH web site at http://ww.cdc.gov/niosh/docs/2000-116/. (Link Updated 4/8/2015)

In addition to retraining workers regarding fall protection, employers should retrain employees to recognize other hazards present at their work sites. In this instance, power cords were placed in areas that created a safety hazard. Power cords should not be used in areas where they are subject to damage or to entanglement, and they should not be located near roof edges where workers can be exposed to fall hazards when attempting to move them. Worker training should help workers recognize the hazard presented by the power cord placement and the need for relocating it or for using battery-operated tools.

Back to Top

References

- Code of Federal Regulations, 2001 edition. 29 CFR 1926.501. Washington, D.C.: U.S. Government Printing Office, Office of the Federal Register.

- Code of Federal Regulations, 2001 edition. 29 CFR 1926.21(b)(2), and 29 CFR 1926.503. Washington, D.C.: U.S. Government Printing Office, Office of the Federal Register.

- Code of Federal Regulations, 2001 edition. 29 CFR 1926.500-503. Washington, D.C.: U.S. Government Printing Office, Office of the Federal Register.

- DOL OSHA information pertaining to fall protection is available at https://www.osha.gov/ .

- NIOSH [2000]. Worker deaths from falls. U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH) Publication No. 2000-116. Also see the NIOSH web site at https://www.cdc.gov/nioshdocs//90-100/. (Link Updated 3/14/2013)

Back to Top

Investigator Information

This investigation was conducted by Doloris N. Higgins, Safety and Occupational Health Specialist, Fatality Assessment and Control Evaluation Team, Surveillance and Field Investigations Branch, Division of Safety Research.

* According to OSHA , a low-slope roof means a roof having a slope less than or equal to 4 in 12 (vertical to horizontal), [29 CFR 1926.500].

** According to OSHA, a competent person is one who is capable of identifying existing and predictable hazards in surroundings or conditions which are unsanitary, hazardous, or dangerous to employees, and who has the authorization to take prompt corrective action to eliminate them (29 CFR 1926.32).

In-house Reports

- Page last reviewed: November 18, 2015

- Page last updated: October 15, 2014

- Content source:

- National Institute for Occupational Safety and Health Division of Safety Research

ShareCompartir

ShareCompartir