1. Introduction

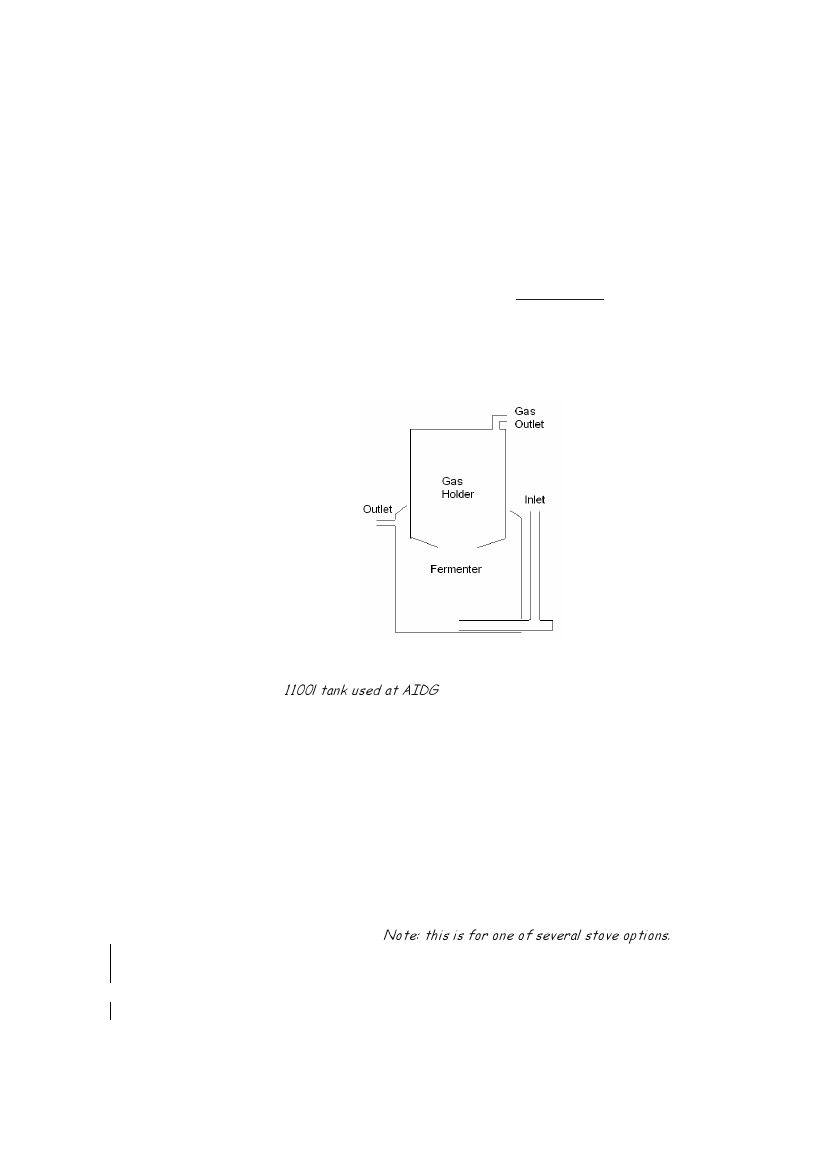

The Appropriate Rural Technology Institute (ARTI) is an NGO based in Maharashtra, India. ARTI has

developed a compact biogas plant which uses waste food rather than manure as feedstock, to supply biogas

for cooking. The compact plants are made from cut-down high-density polythene (HDPE) water tanks, which

are adapted using HDPE or PVC piping. The standard plant uses two tanks, with volumes of typically 0.75 m3

and 1 m3 (750l and 1000l). The smaller tank is the gas holder and is inverted over the larger one which

holds the mixture of decomposing feedstock and water (slurry). An inlet is provided for adding feedstock,

and an overflow for removing the digested effluent/ residue ( www.eawag.ch )

The Appropriate Infrastructure Development Group (AIDG) helps individuals and communities to benefit

from affordable and environmentally sound access to electricity, sanitation and clean water. AIDG’s

strategy focuses on business incubation, education and outreach and its projects are based in Guatemala

and Haiti.

2. Materials List

1000l plastic water tank (1100l tank used at AIDG); 750l plastic water tank; 2m of x PVC pipe; PVC glue.

Feedstock Inlet: 2 x 4” PVC to male threaded fitting; 1 x 4” PVC to female threaded fitting; 1 x 4” PVC T;

1 x 4” female cap; scrap sheet metal (for funnel: 115cm x 35cm x 20cm long); 5 rivets.

Residue Outlet: 1 x 4” PVC to male threaded fitting; 1 x 4” PVC to female threaded fitting; 1 x 4” PVC

elbow.

Small tank upper inlet 1 ½” female cap (assuming the inlet is male threaded. This is to seal the hole)

Seals 80 x 80 cm x 2mm thick rubber (like bike inner tube rubber); 25cm x 25cm x 6mm thick spongy

rubber; silicone; PTFE (Teflon) tape.

Float Limiting Structure: 11m of 1” PVC; 4 1” PVC elbows; 0.5 x 6cm Bolts (4); 0.5cm Nuts (4); 0.5cm

Washers (24); Flat iron (approx. 3.5m x 2cm x 2mm thick.)

Gas outlet 1 ½ “ coupler; 1 ½ - ¾ “ male to female reducer ; ¾- ½“ male thread to female thread reducer; ½

“ male threaded adaptor to flexible hose; ½ “flexible hose; ½ “ hose clamp.

Gas Burner: ½ “ hose clamp; 2 x ½ “ metal nipple; ½ “ shut off valve; 1.5cm Ø iron bar + 2.5cm Ø tubular iron

iron bar to be welded into a stove frame Note: this is for one of several stove options.

3. Tools List

Jigsaw; Tape measure; Flat file; Marker pen; Two large pipe wrenches; Small adjustable spanner ; Welding

machine (helps to make the float limiting structure); Scissors; Hammer; Chisel; Hacksaw; Drill; Rivet gun

2